loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1354 frp vessel

The Evolution and Applications of 1354 FRP Vessels

In recent years, the need for advanced materials in various industries has led to significant developments in the design and manufacturing of vessels. One notable innovation in this realm is the 1354 FRP (Fiber-Reinforced Plastic) vessel, which has garnered attention for its durability, lightweight properties, and resistance to corrosion. This article explores the various aspects of 1354 FRP vessels, including their composition, advantages, applications, and future prospects.

Understanding FRP Technology

Fiber-Reinforced Plastic is a composite material consisting of a polymer matrix reinforced with fibers. The fibers, usually made from glass, carbon, or aramid, enhance the mechanical properties of the polymer, resulting in a material that offers tremendous strength coupled with reduced weight. The term 1354 in 1354 FRP vessels specifically refers to a standardized type, which implies certain characteristics and quality benchmarks that make these vessels suitable for various applications.

Composition and Manufacturing

The typical composition of a 1354 FRP vessel involves a thermoset polymer matrix, primarily epoxy or polyester, that binds the reinforcing fibers. During the manufacturing process, a series of layers of fibers are laid and infused with the resin, which is then cured under controlled conditions. This layer-by-layer approach not only enhances the strength of the vessel but also allows for customization in design and functionality.

The manufacturing of FRP vessels often involves advanced techniques such as filament winding, pultrusion, or hand lay-up processes. These techniques enable manufacturers to produce vessels that meet strict industry standards for pressure, temperature, and chemical resistance, setting the stage for their widespread adoption.

Advantages of 1354 FRP Vessels

1. Corrosion Resistance One of the primary advantages of FRP vessels is their ability to resist corrosion from various chemicals. Unlike traditional materials like steel or aluminum, FRP does not rust or corrode, which extends the lifespan of the vessels and minimizes maintenance costs.

2. Lightweight The lightweight nature of FRP vessels makes them easier to transport and install. This characteristic is particularly beneficial in industries such as oil and gas, where ease of mobility can reduce installation time and labor costs.

1354 frp vessel

3. Strength and Durability Despite being lightweight, 1354 FRP vessels possess high tensile strength, making them capable of withstanding high pressure and impacting forces. This durability is critical in applications that require resilience against extreme conditions.

4. Thermal Insulation FRP materials provide excellent thermal insulation, allowing vessels to maintain their contents at desired temperatures, which is particularly useful in chemical processing industries.

5. Cost-Effectiveness Although the initial investment for FRP vessels can be higher than traditional materials, the long-term benefits—such as reduced maintenance costs and increased durability—make them a more cost-effective solution over time.

Applications

1354 FRP vessels are utilized across various industries, including

- Chemical Processing Their resistance to harsh chemicals makes them ideal for storing and transporting reactive substances. - Water Treatment FRP vessels are commonly used in water treatment systems, providing reliable storage tanks that do not leach contaminants into the water. - Oil and Gas In the oil and gas sector, FRP vessels are used for storage tanks and pressure vessels, where durability and lightweight characteristics are crucial. - Marine Applications Their resistance to saltwater corrosion makes them suitable for various marine applications, including boat hulls and storage tanks.

Future Prospects

As technology evolves and the demand for sustainable solutions continues to rise, the future of 1354 FRP vessels looks promising. Advances in manufacturing techniques and materials science may further enhance the performance of these vessels, opening new avenues for their application in fields such as renewable energy and aerospace.

In conclusion, the 1354 FRP vessel represents a significant advancement in material technology, offering numerous benefits over traditional vessel materials. Its unique properties make it a versatile and reliable choice for various industries, paving the way for innovation and improved efficiency. As industries seek to optimize their processes and reduce their environmental impact, FRP vessels will undoubtedly play a crucial role in shaping the future of engineering and manufacturing.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

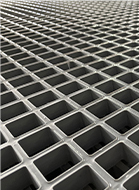

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025