loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Effects of Marine Grating on Aquatic Ecosystems and Biodiversity Conservation

Understanding Marine Grating A Vital Component for Maritime Safety and Efficiency

Marine grating plays a crucial role in various maritime applications, with its importance spanning from safety measures to structural integrity in marine environments. As a vital component used in shipbuilding, offshore platforms, and coastal structures, marine grating provides both functionality and safety in harsh conditions. This article delves into the different types of marine grating, their applications, and the materials used in their construction, alongside their significance in enhancing operational efficiency and safety in maritime settings.

What is Marine Grating?

Marine grating is a type of flooring system designed specifically for marine environments. It is typically used on walkways, decks, and platforms to provide a safe, stable surface for both personnel and equipment. Grating systems are characterized by their open surface structure, which allows for the passage of water and light, thus preventing the accumulation of rainwater and reducing the risk of slippery surfaces.

There are several types of grating, but the most commonly used in marine applications are fiberglass-reinforced plastic (FRP) gratings, stainless steel gratings, and aluminum gratings. Each type serves unique needs based on the environment and operational requirements.

Types of Marine Grating

1. Fiberglass Reinforced Plastic (FRP) Grating FRP grating is favored in marine settings because it is lightweight, corrosion-resistant, and requires minimal maintenance. The non-slip surface ensures safety for workers navigating wet decks. Additionally, the inherent UV resistance of FRP materials makes them ideal for outdoor use where sunlight is prevalent.

2. Stainless Steel Grating Known for its strength and durability, stainless steel grating is another common choice for marine applications, particularly in areas exposed to harsh environments, such as saltwater or chemical spills. While heavier than FRP, stainless steel offers superior load-bearing capabilities, making it ideal for heavy machinery or high-traffic areas.

3. Aluminum Grating While aluminum grating is lightweight and resistant to corrosion, it is generally used in less demanding environments. Its applications typically include walkways and platforms where the load-bearing capacity is not as significant.

Applications of Marine Grating

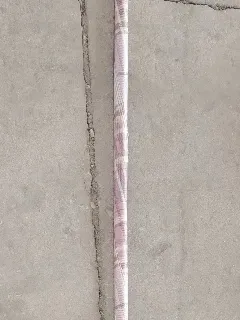

marine grating

Marine grating finds applications in various domains, including

- Shipbuilding and Repair Grating systems are essential in shipbuilding facilities, providing safe surfaces for workers while they conduct repairs and maintenance tasks on vessels.

- Offshore Platforms On oil rigs and other offshore installations, grating provides non-slip surfaces where personnel work around heavy equipment and machinery, enhancing overall safety.

- Coastal Infrastructure Marine grating is used in the construction of docks, piers, and walkways, ensuring safe pedestrian access in coastal environments.

- Water Treatment Facilities Grating systems can be found in water treatment plants where they support filtration systems and maintenance walks, safeguarding workers and improving operational access.

Importance of Marine Grating

The significance of marine grating extends beyond just functionality; it plays an essential role in enhancing safety and efficiency in maritime operations. The open design of grating systems facilitates quick drainage, minimizing the risk of slips and falls due to water accumulation. Furthermore, the lightweight nature, particularly of FRP grating, aids in the overall weight management of vessels and structures, contributing to improved performance and fuel efficiency.

Additionally, the choice of material impacts long-term costs. Corrosion-resistant materials like FRP and stainless steel can significantly reduce maintenance expenses over time, making them a wise investment for any maritime operation.

Conclusion

In summary, marine grating is an indispensable element in the maritime industry, ensuring safe, efficient work environments amidst the strenuous demands of marine conditions. By understanding the types, applications, and importance of marine grating, stakeholders can make informed decisions that enhance safety and operational efficiency on vessels and structures alike. As maritime activities continue to evolve, the role of marine grating will remain vital, upholding the standards of safety and structural integrity crucial for successful maritime operations.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025