loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advancements in Glass Fiber Reinforced Polymer Rebar for Construction Applications

Glass Fiber Reinforced Polymer Rebar A Revolution in Construction

In the evolving world of construction materials, Glass Fiber Reinforced Polymer (GFRP) rebar is increasingly gaining attention as a superior alternative to traditional steel reinforcement. This innovative material combines the advantages of lightweight structural integrity and resistance to environmental factors, making it an attractive choice for various construction applications.

What is GFRP?

GFRP is composed of a polymer matrix reinforced with glass fibers. The fibers provide exceptional tensile strength, while the polymer offers resistance to corrosion and chemical damage. The result is a product that not only maintains structural performance but also reduces the overall weight of construction elements. Unlike traditional steel rebar, which is susceptible to rusting and degradation over time, GFRP remains unaffected by moisture, chloride ions, and other chemicals commonly found in construction environments.

Benefits of GFRP Rebar

1. Corrosion Resistance One of the most significant advantages of GFRP rebar is its excellent resistance to corrosion. In areas where concrete structures are exposed to de-icing salts, seawater, or industrial chemicals, traditional steel rebar often suffers from rust, leading to structural weakening and costly repairs. GFRP's immunity to such conditions ensures longevity and reliability, making it particularly valuable in marine and severe-weather applications.

2. Lightweight Structure GFRP is significantly lighter than steel, often weighing about one-quarter of the equivalent steel rebar. This reduced weight not only simplifies handling during construction but also minimizes the overall load on structures. The lower weight can contribute to reduced foundation requirements, lowering material and labor costs.

3. Electromagnetic Transparency Unlike steel, GFRP is non-metallic and does not impede electromagnetic signals. This characteristic makes it ideal for applications where radio transmission and radar detection are critical, such as in bridges and tunnels where communication systems are essential.

4. Enhanced Design Flexibility GFRP can be produced in various shapes and sizes, providing architects and engineers with enhanced design flexibility. The ability to mold GFRP into different configurations allows for innovative architectural designs that were previously challenging with traditional materials.

glass fiber reinforced polymer rebar

5. Sustainability As the construction industry increasingly prioritizes sustainability, GFRP's reduced energy requirements during manufacturing and its ability to withstand the elements make it an eco-friendly choice. Additionally, its lightweight nature can lead to lower fuel consumption during transportation, further reducing the overall carbon footprint of construction projects.

Applications of GFRP Rebar

The applications of GFRP rebar are extensive. It is widely used in bridge construction, particularly in parts that are prone to corrosion, such as piers and decks. Additionally, GFRP has gained traction in the construction of parking garages, coastal structures, and water treatment facilities where exposure to harsh chemicals and moisture is common.

Moreover, its use is expanding to residential construction, especially in areas prone to flooding or severe weather, where durability is critical. GFRP's strength and resistance to environmental degradation enhance the safety and longevity of structures, making it an increasingly popular choice among builders and contractors.

Challenges Ahead

Despite its numerous advantages, GFRP rebar faces some challenges. The initial cost of GFRP can be higher than that of traditional steel. However, proponents argue that this is offset by the reduced maintenance and longevity the material offers. Furthermore, the lack of widespread familiarity among construction professionals may pose a barrier to its acceptance. As more projects successfully integrate GFRP and demonstrate its benefits, broader acceptance is likely to follow.

Conclusion

Glass Fiber Reinforced Polymer rebar represents a significant advancement in construction technology. With its unique combination of strength, lightweight characteristics, and resistance to corrosion, it offers a viable and sustainable alternative to traditional steel reinforcement. As the construction industry continues to seek innovative solutions to overcome challenges posed by climate change and sustainability demands, GFRP rebar is poised to play a crucial role in shaping the future of building materials. Its growing adoption and proven track record will undoubtedly contribute to the creation of safer, longer-lasting structures for generations to come.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

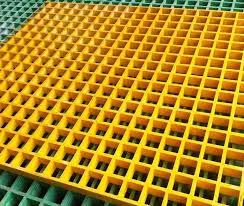

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025