loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 14, 2025 12:10

Back to list

frp pultruded gratings

FRP moulded gratings have steadily emerged as a leading choice in various industrial applications, primarily due to their superior performance and durability compared to traditional materials like steel or aluminium. Crafted from high-quality fiberglass reinforcements and resins, these gratings offer a unique set of advantages that address the specific needs of industries ranging from chemical processing to wastewater management.

From an environmental perspective, FRP moulded gratings also offer significant benefits. They are non-conductive and do not release toxic fumes, making them an environmentally friendly choice. This aspect resonates well with companies looking to adopt more sustainable practices, thereby boosting their corporate social responsibility profiles. An additional advantage lies in the thermal properties of FRP moulded gratings. They exhibit excellent thermal insulation, which is beneficial for industries operating in extreme temperature environments. This characteristic helps in maintaining comfortable and safe conditions for personnel, as well as protecting sensitive equipment from temperature fluctuations. The expertise and authority of FRP moulded grating manufacturers are reflected in their commitment to continuous innovation and improvement. Manufacturers often conduct rigorous testing to ensure compliance with international standards, providing customers with the assurance of superior quality and performance. The credibility of these products is further reinforced by numerous case studies and testimonials from industries that have successfully implemented FRP moulded gratings, witnessing tangible improvements in both safety and operational efficiency. In conclusion, FRP moulded gratings present a modern, effective solution for myriad industrial applications. Their advantages in terms of corrosion resistance, strength, safety, and environmental friendliness make them an outstanding choice for companies seeking to improve their infrastructure while maintaining cost-efficiency. With a continued focus on innovation, the future of FRP moulded gratings appears promising, as they steadily gain recognition for their unmatched performance and reliability in the industrial realm.

From an environmental perspective, FRP moulded gratings also offer significant benefits. They are non-conductive and do not release toxic fumes, making them an environmentally friendly choice. This aspect resonates well with companies looking to adopt more sustainable practices, thereby boosting their corporate social responsibility profiles. An additional advantage lies in the thermal properties of FRP moulded gratings. They exhibit excellent thermal insulation, which is beneficial for industries operating in extreme temperature environments. This characteristic helps in maintaining comfortable and safe conditions for personnel, as well as protecting sensitive equipment from temperature fluctuations. The expertise and authority of FRP moulded grating manufacturers are reflected in their commitment to continuous innovation and improvement. Manufacturers often conduct rigorous testing to ensure compliance with international standards, providing customers with the assurance of superior quality and performance. The credibility of these products is further reinforced by numerous case studies and testimonials from industries that have successfully implemented FRP moulded gratings, witnessing tangible improvements in both safety and operational efficiency. In conclusion, FRP moulded gratings present a modern, effective solution for myriad industrial applications. Their advantages in terms of corrosion resistance, strength, safety, and environmental friendliness make them an outstanding choice for companies seeking to improve their infrastructure while maintaining cost-efficiency. With a continued focus on innovation, the future of FRP moulded gratings appears promising, as they steadily gain recognition for their unmatched performance and reliability in the industrial realm.

Share

Latest news

-

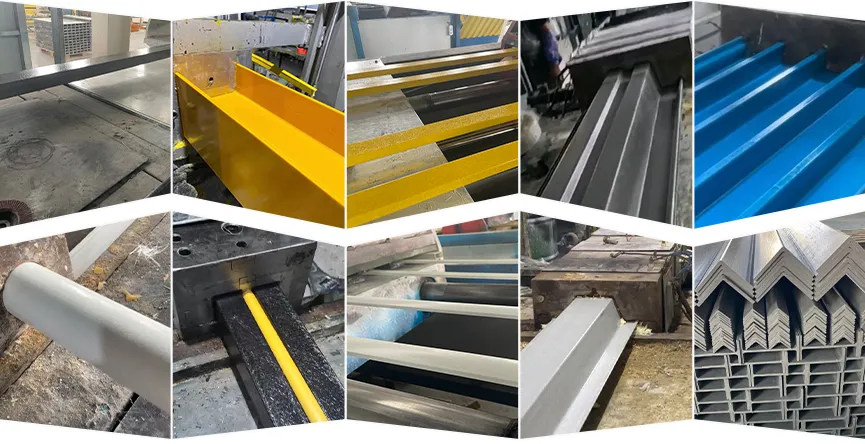

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

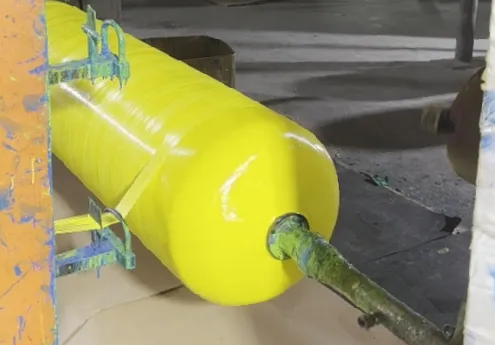

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025