loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

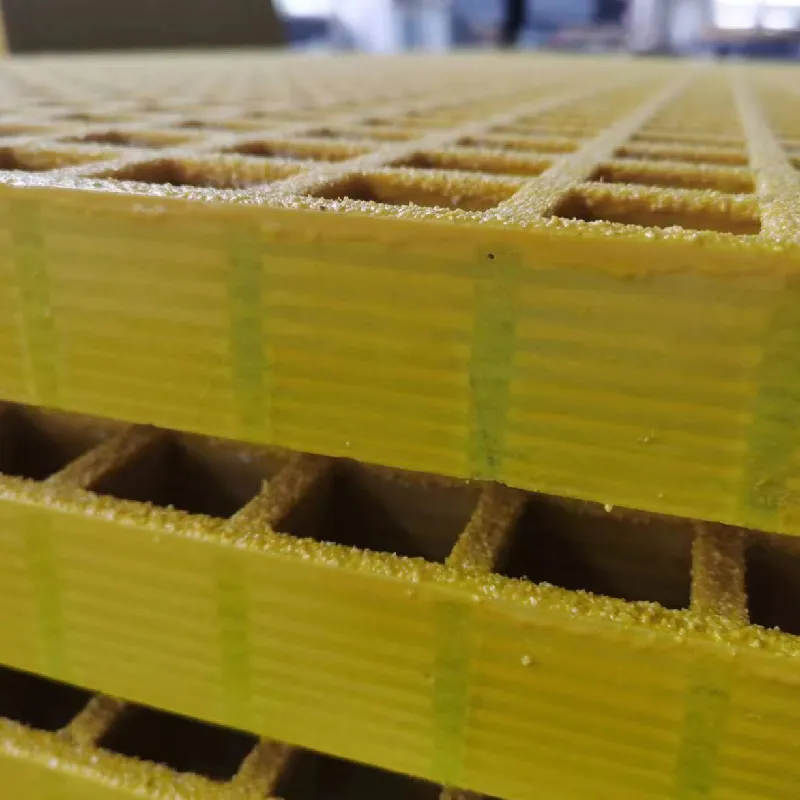

FRP Grating The Superior Industrial Flooring Solution

In the demanding world of industrial and construction materials, the quest for a flooring solution that combines immense strength with unwavering corrosion resistance has long been a challenge. For decades, steel and aluminum were the default choices, but they come with significant drawbacks, including weight, maintenance, and susceptibility to corrosive environments. This is where ZJ Composites enters the picture, revolutionizing the industry with our advanced frp grating. We are committed to the principle of "Better Composites, Better than Metal," and our comprehensive range of fiberglass reinforced plastic products is a testament to that mission. As a leading manufacturer and wholesaler, we specialize in producing high-performance frp grating panels that are engineered to outperform traditional materials, offering a smarter, more durable, and cost-effective alternative for a multitude of applications across the globe. Our vision is to cultivate brand loyalty by consistently delivering products that not only meet but exceed the rigorous demands of our wholesale partners, ensuring their projects are built on a foundation of quality and innovation.

Understanding the Basics of Frp Grating

To fully appreciate the advantages of our products, it is essential to understand what pultruded frp grating is and how it is manufactured. FRP, or Fiberglass Reinforced Plastic, is a composite material consisting of glass fibers embedded in a polymer resin matrix. At ZJ Composites, we employ a state-of-the-art pultrusion process, a continuous and highly controlled manufacturing technique that pulls the glass fibers through a resin bath and then through a heated die. This process aligns the fibers, creating a profile of exceptional strength and consistency. The result is a pultruded frp grating system that boasts a high strength-to-weight ratio, making it significantly lighter than steel yet remarkably strong. This fundamental understanding of material science and our commitment to standardized, modern enterprise management allows us to produce frp grating panels that are uniform in quality and performance. Our strong technical support and perfect testing equipment ensure that every panel that leaves our facility adheres to the strictest international standards, providing a reliable and predictable building block for your large-scale projects.

Key Advantages of Our Frp Grating Panels

The shift from traditional metallic grating to our frp grating panels is driven by a host of compelling benefits that directly impact the long-term viability and safety of industrial installations. First and foremost is their exceptional corrosion resistance. Unlike steel, which rusts, and aluminum, which can corrode, our FRP grating is inherently immune to a wide range of chemical attacks, making it ideal for environments such as water treatment plants, chemical processing facilities, offshore platforms, and food and beverage plants where exposure to harsh substances is a daily occurrence. This corrosion resistance translates directly to a significant reduction in lifetime costs, as it eliminates the need for frequent painting, coating, or replacement. Secondly, the non-conductive nature of fiberglass makes our frp grating panels the safest choice for electrical substations, power generation facilities, and any area where electrical hazards are a concern. Furthermore, the molded-in surface of our grating provides excellent slip resistance, even in wet or oily conditions, enhancing worker safety and reducing the risk of accidents on site.

Exploring the Different Types of Frp Grate

At ZJ Composites, we recognize that a one-size-fits-all approach does not work for the diverse needs of our global wholesale clientele. Therefore, we have innovated a varied product line to provide optimal solutions for every specific application. Our primary offering is the pultruded frp grating, which is known for its superior mechanical properties and straight, clean lines, making it perfect for high-load applications like industrial walkways, platforms, and trench covers. For situations requiring maximum open area for light transmission, air flow, or fluid drainage, we offer the frp mesh grating variant. This design provides an exceptionally high percentage of open area while maintaining structural integrity. Both types of frp grating can be manufactured using different resin systems—such as polyester, vinyl ester, or phenolic—to tailor the product's chemical and fire-retardant properties to the specific environmental challenges of your project. This flexibility, born from our scientific and technology-based approach, ensures that we can provide the best services and the most appropriate frp grating panels for any industrial scenario.

Ideal Applications for Durable Frp Mesh Grating

The unique properties of our products make them indispensable across a wide spectrum of industries. The lightweight yet robust nature of our frp grating makes installation faster, easier, and safer, reducing labor costs and project timelines. In the water and wastewater treatment industry, our frp mesh grating is extensively used for walkways, catwalks, and tank covers because it can withstand constant exposure to moisture, chemicals, and atmospheric corrosion without degrading. In the electrical and power generation sector, the dielectric strength of our pultruded frp grating ensures a safe working environment around high-voltage equipment. The marine and offshore industries rely on our frp grating panels for decking, docks, and shipboard platforms due to their resistance to saltwater corrosion. Additionally, the food and beverage, mining, and pulp and paper industries all benefit from the non-sparking, non-conductive, and low-maintenance characteristics of our grating systems. Our products are sold all over the world and are deeply trusted by users because they deliver consistent performance where it matters most.

FRP Grating FAQ

What are the primary safety benefits of using frp grating in corrosive environments?

The primary safety benefits include exceptional corrosion resistance that prevents structural weakening, inherent non-conductivity for protection against electrical hazards, and excellent slip resistance for fall prevention.

How does the load-bearing capacity of pultruded frp grating compare to traditional steel grating?

While significantly lighter, our pultruded frp grating offers a strength-to-weight ratio that is competitive with steel, capable of handling heavy loads in industrial settings, making it a superior replacement in many applications.

In what applications is frp mesh grating a more suitable choice than standard frp grating panels?

Frp mesh grating is ideal where maximum open area is critical, such as for high-flow drainage in water treatment, air circulation in ventilation screens, or light transmission in skylight areas.

What resin systems are available for your frp grating panels to handle specific chemical exposures?

We offer various resin systems including general-purpose polyester, corrosion-resistant vinyl ester for harsh chemicals, and fire-retardant phenolic to meet specific project requirements for our frp grating panels.

As a wholesaler, what kind of technical and logistical support can ZJ Composites provide for large projects involving pultruded frp grating?

We provide comprehensive technical data, CAD drawings, load tables, and project-specific consultation, backed by a streamlined logistics system to ensure timely delivery and support for your large-scale projects.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025