loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable Composite Grate Panels for Enhanced Performance and Longevity in Various Applications

The Benefits and Applications of Fiberglass Grate Panels

Fiberglass grate panels are increasingly becoming a favored choice across various industries due to their remarkable properties and versatile applications. By harnessing the strength of fiberglass, these panels provide a practical solution for businesses seeking durable, lightweight, and corrosion-resistant materials.

What Are Fiberglass Grate Panels?

Fiberglass grate panels consist of reinforced fiberglass, created by combining glass fibers with resin. This composite material is known for its high strength-to-weight ratio, which allows it to support heavy loads without compromising structural integrity. The grates can be designed in various configurations, including different sizes and shapes, making them suitable for a range of environments.

Durability and Longevity

One of the most significant advantages of fiberglass grate panels is their exceptional durability. Unlike traditional materials like wood or metal, fiberglass does not corrode, rust, or decay over time. This resistance to environmental factors ensures that fiberglass panels maintain their structural integrity even in harsh conditions, such as those found in chemical plants or marine environments. Consequently, businesses can expect a longer lifespan from their investments, reducing replacement and maintenance costs.

Lightweight and Easy to Handle

Fiberglass is notably lighter than many conventional materials, which simplifies transportation and installation. Workers can easily maneuver the panels, leading to reduced labor costs and increased efficiency on job sites. Moreover, the lightweight nature of fiberglass also reduces the load on supporting structures, allowing for greater flexibility in design and application.

Corrosion Resistance

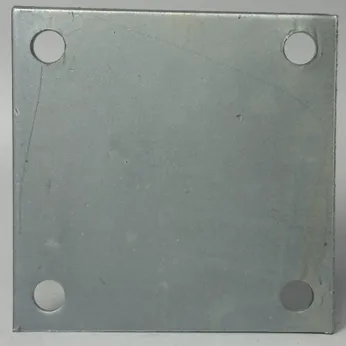

fiberglass grate panels

Another key benefit of fiberglass grate panels is their resistance to corrosion. Unlike steel, which can be susceptible to rust, fiberglass can withstand exposure to a wide array of chemicals, making it an excellent choice for industries like wastewater treatment, food processing, and chemical manufacturing. This resistance extends the life of the panels, minimizing the need for frequent replacements due to damage from corrosive substances.

Safety Features

Fiberglass grates are designed with safety in mind. They often feature slip-resistant surfaces, providing additional grip in environments where spills or wet conditions may occur. Furthermore, the structural design of these panels allows for a high degree of visibility, ensuring that workers can see hazards more clearly. This combination of features helps to create a safer working environment, reducing the risk of accidents and injuries.

Versatile Applications

Fiberglass grate panels are utilized in a broad spectrum of applications. In industrial settings, they are commonly used for walkways, platforms, and scaffolding. Their non-conductive properties make them suitable for electrical installations as well. In commercial spaces, fiberglass grating is often employed for drainage covers, decking, and covers for various types of pits.

Moreover, in recreational areas, fiberglass panels can be found in pool decking and boardwalks, where their slip-resistant features and aesthetic appeal make them an attractive choice. Their adaptability and range of designs also allow architects and engineers to incorporate fiberglass panels into creative building designs.

Conclusion

Fiberglass grate panels are revolutionizing how industries approach flooring and walkways. With their durable, lightweight, and corrosion-resistant properties, they provide a reliable solution for various applications. As organizations prioritize safety and longevity in their material choices, fiberglass grates are becoming increasingly popular, underscoring the significance of modern materials in meeting the demands of diverse environments. As technology advances, the design and production of fiberglass grating will only continue to improve, broadening its applications and enhancing its performance in the future.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025