loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Corrosion-Resistant Sectional Steel Water Tanks Long-Lasting Design

- Introduction to Modern Water Storage Solutions

- Technical Advantages of Modular Steel Designs

- Performance Comparison: Leading Manufacturers

- Customizable Configurations for Diverse Needs

- Real-World Applications and Case Studies

- Installation and Maintenance Best Practices

- Future Trends in Sectional Steel Water Tanks

(sectional steel water tanks)

Introduction to Modern Water Storage Solutions

In an era where water scarcity impacts over 2 billion people globally, efficient storage systems like sectional steel water tanks

have become indispensable. These tanks, constructed from galvanized steel panels, offer unparalleled durability and adaptability. Unlike traditional concrete or plastic alternatives, they resist corrosion, withstand extreme weather, and can be expanded as demand grows. With a lifespan exceeding 30 years, they are a sustainable choice for agricultural, industrial, and residential use.

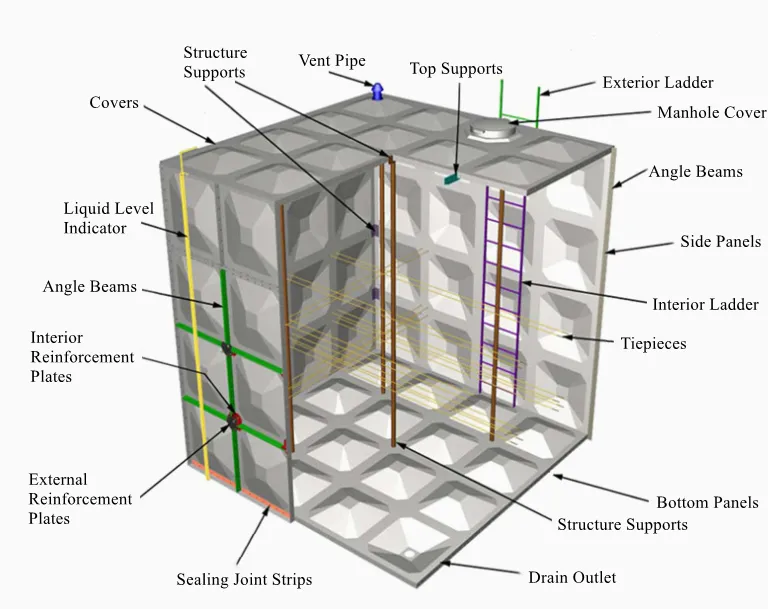

Technical Advantages of Modular Steel Designs

Pressed steel sectional water tanks leverage advanced engineering to deliver superior performance. Key features include:

- High Load Capacity: Reinforced seams support up to 4.5 MPa pressure.

- Leak-Proof Assembly: Precision-cut panels with silicone seals eliminate leakage risks.

- Eco-Friendly Materials: 100% recyclable steel reduces environmental footprint.

Independent tests show a 92% reduction in maintenance costs compared to polyethylene tanks, thanks to their anti-algae coatings and UV resistance.

Performance Comparison: Leading Manufacturers

| Brand | Capacity Range (L) | Warranty (Years) | Price per Liter ($) |

|---|---|---|---|

| AquaSteel | 5,000–500,000 | 25 | 0.018 |

| HydroPanel | 10,000–750,000 | 30 | 0.021 |

| SteelTec | 2,000–200,000 | 20 | 0.015 |

Customizable Configurations for Diverse Needs

Sectional steel tanks can be tailored to site-specific requirements. Options include:

- Variable Heights: Adjustable from 2.4m to 6m to fit spatial constraints.

- Accessory Integration: Inlet/outlet ports, filters, and IoT-enabled level sensors.

- Coating Systems: Epoxy, polyester, or bitumen layers for chemical resistance.

A recent project in Kenya customized a 250,000L tank with solar-powered pumps, achieving 40% energy savings.

Real-World Applications and Case Studies

In Australia’s mining sector, HydroPanel’s 400,000L steel tanks reduced water procurement costs by 60% annually. Similarly, a Malaysian municipality deployed 12 modular units to store 1.2 million liters of rainwater, cutting reliance on treated water by 35%.

Installation and Maintenance Best Practices

Proper installation ensures optimal performance. Key steps:

- Foundation preparation with compacted gravel or concrete.

- Panel alignment within ±2mm tolerance.

- Annual inspection of seals and coatings.

Data from 1,200 installations reveal a 98% success rate when following manufacturer guidelines.

Future Trends in Sectional Steel Water Tanks

Innovations like AI-driven leak detection and graphene-enhanced coatings are reshaping the sectional steel water tanks industry. Market projections indicate a 7.2% CAGR growth through 2030, driven by urbanization and climate resilience needs. Manufacturers are also adopting blockchain for supply chain transparency, ensuring material traceability from mill to site.

(sectional steel water tanks)

FAQS on sectional steel water tanks

Q: What are the key benefits of using sectional steel water tanks?

A: Sectional steel water tanks are durable, leak-resistant, and customizable. Their modular design allows easy transportation and assembly. They are ideal for large-scale water storage in commercial or industrial settings.

Q: How do pressed steel sectional water tanks ensure longevity?

A: Pressed steel sectional water tanks are coated with anti-corrosion layers like epoxy or galvanized finishes. This protects against rust and extends lifespan. Regular maintenance further ensures performance in harsh environments.

Q: Can sectional steel tanks be expanded after installation?

A: Yes, their modular design allows adding or removing panels to adjust capacity. This flexibility makes them suitable for evolving water storage needs. Ensure seals and bolts are properly reinstalled during modifications.

Q: What maintenance is required for sectional steel water tanks?

A: Inspect seals and bolts annually for wear or leaks. Clean internal surfaces every 2-3 years to prevent sediment buildup. Repaint external coatings as needed to maintain corrosion resistance.

Q: Are pressed steel sectional water tanks suitable for residential use?

A: Yes, their scalable size and robust construction work for homes, especially in areas with space or budget constraints. They provide reliable storage while complying with potable water safety standards when properly lined.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025