loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

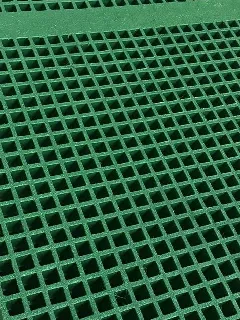

pultruded frp grating

Understanding Pultruded FRP Grating A Comprehensive Overview

In recent years, the demand for durable, lightweight, and corrosion-resistant materials has surged across various industries. One such material that has gained considerable traction is pultruded Fiber Reinforced Polymer (FRP) grating. This innovative product offers a host of advantages, making it a favorable choice for applications ranging from industrial flooring to pedestrian walkways.

What is Pultruded FRP Grating?

Pultrusion is a manufacturing process that involves pulling continuous fiber bundles through a resin bath and then through a heated die to form a rigid composite material. The result is a highly consistent product that exhibits excellent strength-to-weight ratios. Pultruded FRP grating consists of a series of fiberglass-reinforced polymer bars arranged in a grid pattern, which provides an open area for drainage and airflow while maintaining structural integrity.

Key Advantages of Pultruded FRP Grating

1. Corrosion Resistance One of the most significant benefits of pultruded FRP grating is its resistance to corrosion. Unlike traditional materials such as steel, which can degrade quickly in harsh environments, FRP grating does not rust or corrode when exposed to chemicals, moisture, or saline conditions. This property makes it particularly suitable for industries such as wastewater treatment, chemical processing, and marine applications.

2. Lightweight and Strong Pultruded FRP grating is exceptionally lightweight compared to metal grating systems. This characteristic not only reduces transportation and installation costs but also minimizes the load on structural supports. Despite its light weight, FRP grating maintains impressive strength, making it an ideal choice for load-bearing applications.

3. Safety Features The slip-resistant surface of pultruded FRP grating enhances safety, especially in environments where wet or oily conditions are prevalent. The grating can also be manufactured with flanged or serrated surfaces to further reduce the risk of slips and falls.

4. Customizability Pultruded FRP grating can be customized in various dimensions, colors, and shapes to fit specific project requirements. This versatility allows for greater design flexibility and adaptation to the unique needs of different applications.

pultruded frp grating

5. Low Maintenance The inherent properties of FRP grating mean that it requires minimal maintenance over its service life. Its resistance to rot, rust, and other forms of degradation minimizes the need for repairs or replacements, making it a cost-effective solution in the long run.

Applications of Pultruded FRP Grating

Due to its advantageous properties, pultruded FRP grating finds a wide array of applications across numerous industries

- Industrial Facilities It is commonly used in factories and manufacturing plants for walkways, platforms, and stair treads due to its ability to withstand heavy loads and chemical exposure.

- Wastewater Treatment Plants The corrosion resistance of FRP grating makes it ideal for environments that are constantly in contact with water and chemicals, such as wastewater treatment facilities.

- Marine Applications In marine environments where traditional materials quickly deteriorate, pultruded FRP grating is used on docks, piers, and boat ramps, providing a sturdy and reliable surface for both pedestrians and vehicles.

- Oil and Gas Sector FRP grating is utilized in oil rigs, refineries, and chemical processing plants due to its resistance to harsh chemicals and its ability to maintain structural integrity under extreme conditions.

Conclusion

Pultruded Fiber Reinforced Polymer grating has established itself as a superior alternative to traditional materials in various applications. Its lightweight nature, exceptional corrosion resistance, safety features, and low maintenance make it an attractive choice for industries requiring reliable, durable solutions. As awareness of its benefits continues to grow, it is expected that pultruded FRP grating will become an even more prevalent choice in construction and manufacturing, paving the way for advancements in material technology and design. Whether for infrastructure projects or specialized industrial applications, pultruded FRP grating is a smart investment for the future.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025