loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

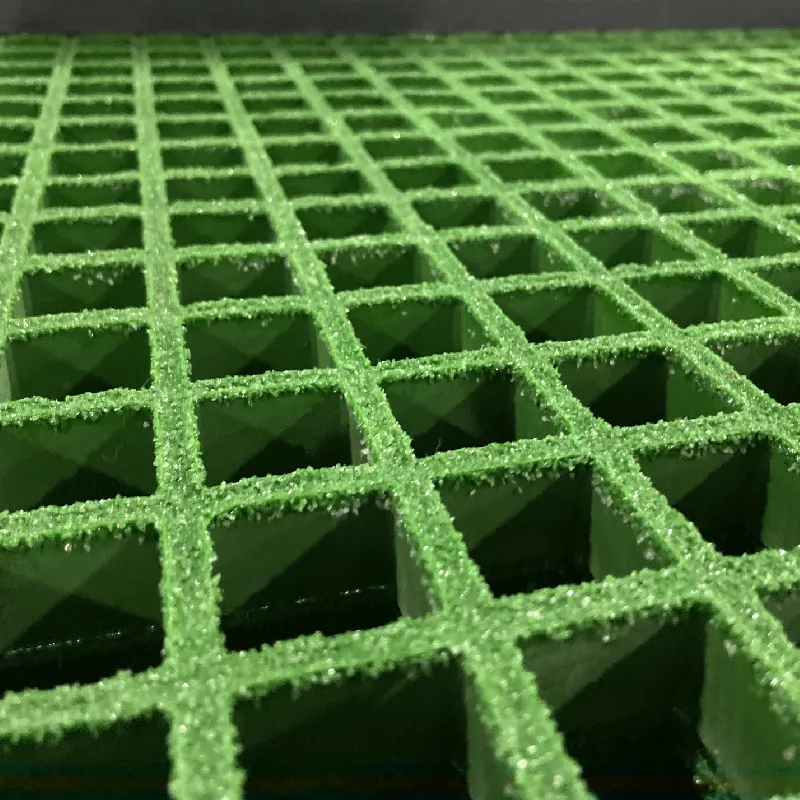

Durable and Lightweight Fiberglass Reinforced Polymer Grating for Various Applications

Fibreglass Reinforced Plastic Grating An Overview

Fibreglass Reinforced Plastic (FRP) grating has emerged as a versatile solution in various industrial and commercial applications. Its unique properties make it an ideal choice for environments where traditional materials might falter. This article explores the benefits, applications, and future of FRP grating, highlighting why it has become a preferred material in many sectors.

What is Fibreglass Reinforced Plastic Grating?

FRP grating is a composite material made from a thermosetting resin, typically polyester, vinyl ester, or epoxy, reinforced with fibreglass. This combination provides a strong yet lightweight alternative to metal and wood grating. The manufacturing process involves weaving glass fibres together with the resin, which is then cured to form a solid, durable structure. The result is a product that offers both strength and resistance to various environmental factors.

Benefits of FRP Grating

1. Durability One of the most significant advantages of FRP grating is its exceptional durability. It is resistant to corrosion, making it ideal for harsh environments such as chemical plants, wastewater treatment facilities, and marine applications. Unlike metal, FRP does not rust, ensuring a longer lifespan.

2. Lightweight FRP grating is considerably lighter than metal grating, facilitating easier handling and installation. This feature is particularly beneficial for applications where reducing weight is crucial, such as in overhead walkways and platforms.

3. Safety The non-slip surface of FRP grating enhances safety in work environments. It minimizes the risk of slips and falls, which can be a significant concern in industrial settings. Furthermore, its Electrical Isolation property makes it suitable for environments with electrical hazards.

4. Low Maintenance FRP grating requires minimal maintenance compared to traditional materials. Its non-porous surface prevents water absorption and the growth of mold, mildew, or algae, leading to lower cleaning and upkeep costs.

5. Customization Manufacturers offer various colors, sizes, and load capacities, allowing for customization based on specific project requirements. This adaptability makes FRP grating suitable for a wide range of uses.

Applications of FRP Grating

fibreglass reinforced plastic grating

FRP grating finds applications across multiple industries due to its unique combination of properties. Some of the prominent sectors where it is used include

- Chemical Processing The corrosive nature of chemicals necessitates robust materials. FRP grating provides a reliable solution for walkways, platforms, and staircases within chemical plants.

- Water Treatment Facilities Water and wastewater treatment plants benefit from the durability and corrosion resistance of FRP grating, which is vital for areas exposed to harsh chemicals.

- Marine Environments The maritime industry often uses FRP grating for docks, piers, and platforms due to its resilience against saltwater corrosion.

- Food Processing Its non-porous surface makes FRP grating an excellent choice for food processing plants, where hygiene is crucial. It is easy to clean and prevents the growth of bacteria.

- Utilities and Power Plants With high electric resistance, FRP grating is often used in utility plants where safety and durability are paramount.

The Future of FRP Grating

As industries continue to search for sustainable and efficient building materials, FRP grating is likely to gain further popularity. The increasing focus on reducing environmental impact aligns with the recyclability of fibreglass materials. Furthermore, ongoing advancements in composite technologies promise to enhance the performance characteristics of FRP grating, making it even more appealing for future applications.

Conclusion

Fibreglass Reinforced Plastic grating represents a significant advancement in material science, providing a robust, lightweight, and versatile solution for various industries. As awareness of its benefits grows, alongside technological improvements, FRP grating is poised to play an increasingly vital role in the development of safe, efficient, and sustainable infrastructure around the globe.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025