loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Peb . 13, 2025 21:07

Back to list

Long Lasting Sanitary SMC FRP Storage Water Tank

Fiberglass tanks represent an innovative solution in fluid storage, offering numerous advantages over traditional materials such as steel and concrete. These tanks are known for their strength, flexibility, and durability, making them an ideal choice for various industries, including chemical processing, water treatment, and food manufacturing.

In the realm of authoritativeness, fiberglass tank manufacturers often employ cutting-edge technology in their production processes. Many utilize computer-aided design (CAD) systems to ensure precision in each tank's construction. Stringent quality control measures are put in place to ensure each tank meets high industry standards. These processes are often backed by certifications from recognized bodies, lending credibility to the manufacturing quality and ensuring trust among clients. Fiberglass tanks also display impressive thermal insulation properties, making them suitable for environments with variable temperature conditions. Whether exposed to extreme heat or cold, these tanks maintain the integrity of the stored content, ensuring that the quality of the product remains uncompromised. This thermal resilience is particularly beneficial for industries such as food processing and beverage manufacturing, where maintaining consistent storage conditions is crucial. Trustworthiness is further reinforced by real-world testimonials from industries that have adopted fiberglass tanks. Numerous case studies highlight their reliability in challenging environments, such as offshore oil platforms and chemical storage facilities. Companies report a significant decrease in storage-related incidents since switching to fiberglass, reinforcing the material's reputation as a dependable choice. Overall, choosing fiberglass tanks is a decision backed by extensive expertise and proven reliability. The innovation and adaptability of fiberglass in meeting the storage demands across diverse sectors underscore its place as a leading material choice. By emphasizing longevity, cost-effectiveness, and flexibility, fiberglass tanks align well with modern industry needs, making them an indispensable component in safe and efficient storage solutions.

In the realm of authoritativeness, fiberglass tank manufacturers often employ cutting-edge technology in their production processes. Many utilize computer-aided design (CAD) systems to ensure precision in each tank's construction. Stringent quality control measures are put in place to ensure each tank meets high industry standards. These processes are often backed by certifications from recognized bodies, lending credibility to the manufacturing quality and ensuring trust among clients. Fiberglass tanks also display impressive thermal insulation properties, making them suitable for environments with variable temperature conditions. Whether exposed to extreme heat or cold, these tanks maintain the integrity of the stored content, ensuring that the quality of the product remains uncompromised. This thermal resilience is particularly beneficial for industries such as food processing and beverage manufacturing, where maintaining consistent storage conditions is crucial. Trustworthiness is further reinforced by real-world testimonials from industries that have adopted fiberglass tanks. Numerous case studies highlight their reliability in challenging environments, such as offshore oil platforms and chemical storage facilities. Companies report a significant decrease in storage-related incidents since switching to fiberglass, reinforcing the material's reputation as a dependable choice. Overall, choosing fiberglass tanks is a decision backed by extensive expertise and proven reliability. The innovation and adaptability of fiberglass in meeting the storage demands across diverse sectors underscore its place as a leading material choice. By emphasizing longevity, cost-effectiveness, and flexibility, fiberglass tanks align well with modern industry needs, making them an indispensable component in safe and efficient storage solutions.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

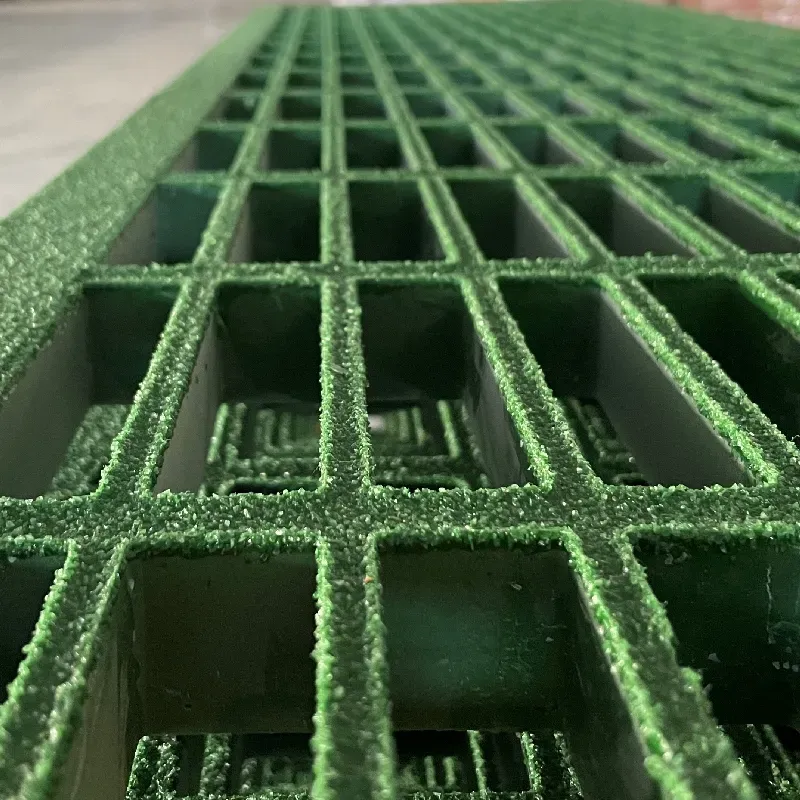

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025