loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

জানু. . 09, 2025 11:50

Back to list

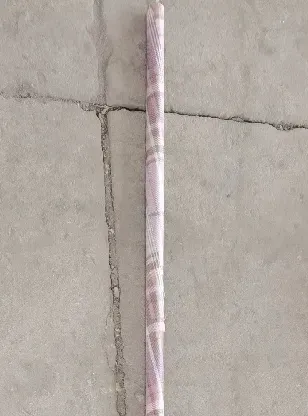

Anti- Corrosion Cost Effective FRP Pultrusion Grating

Pultruded FRP grating is an innovative solution revolutionizing industries that require strong, durable, and lightweight materials. As a seasoned expert in materials technology, I can attest to the remarkable benefits this product brings to diverse applications.

In terms of expertise, the pultrusion process allows for the creation of a product with consistent quality and structural integrity. Manufacturers with cutting-edge technology and strict quality control systems ensure that each piece of grating meets industry standards, offering clients a product they can trust implicitly. Authoritativeness in using pultruded FRP grating is evident through its widespread adoption across numerous industries. From architecture to infrastructure, professionals trust in its proven track record for reducing lifecycle costs and enhancing performance. Case studies from leading companies highlight FRP grating's role in reducing maintenance needs and operational downtimes, providing strong evidence of its viability and reliability. Trustworthiness stems from both the product's intrinsic qualities and the reputation of its producers. Top manufacturers prioritize quality assurance and leverage years of industry experience to produce pultruded FRP grating that consistently exceeds expectations. They often provide detailed certification and testing information, underpinning their product's reliability. As industries continue to seek sustainable and efficient alternatives to traditional materials, pultruded FRP grating emerges as a forward-thinking choice. Its ability to withstand the test of time and environmental challenges makes it a compelling option for forward-thinking businesses aiming to stay competitive while prioritizing safety and cost-effectiveness. In conclusion, pultruded FRP grating isn't just a product; it represents a fusion of innovation and reliability that industrial sectors increasingly rely upon. By choosing this material, you are investing in a solution engineered to perform flawlessly, ensuring safety, efficiency, and sustainability in every project.

In terms of expertise, the pultrusion process allows for the creation of a product with consistent quality and structural integrity. Manufacturers with cutting-edge technology and strict quality control systems ensure that each piece of grating meets industry standards, offering clients a product they can trust implicitly. Authoritativeness in using pultruded FRP grating is evident through its widespread adoption across numerous industries. From architecture to infrastructure, professionals trust in its proven track record for reducing lifecycle costs and enhancing performance. Case studies from leading companies highlight FRP grating's role in reducing maintenance needs and operational downtimes, providing strong evidence of its viability and reliability. Trustworthiness stems from both the product's intrinsic qualities and the reputation of its producers. Top manufacturers prioritize quality assurance and leverage years of industry experience to produce pultruded FRP grating that consistently exceeds expectations. They often provide detailed certification and testing information, underpinning their product's reliability. As industries continue to seek sustainable and efficient alternatives to traditional materials, pultruded FRP grating emerges as a forward-thinking choice. Its ability to withstand the test of time and environmental challenges makes it a compelling option for forward-thinking businesses aiming to stay competitive while prioritizing safety and cost-effectiveness. In conclusion, pultruded FRP grating isn't just a product; it represents a fusion of innovation and reliability that industrial sectors increasingly rely upon. By choosing this material, you are investing in a solution engineered to perform flawlessly, ensuring safety, efficiency, and sustainability in every project.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025