loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

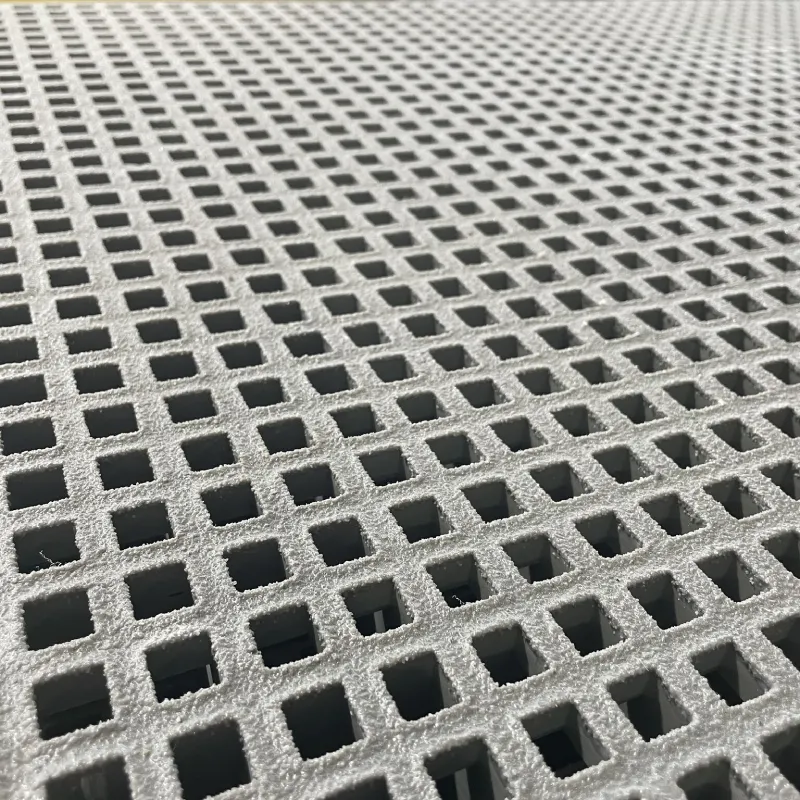

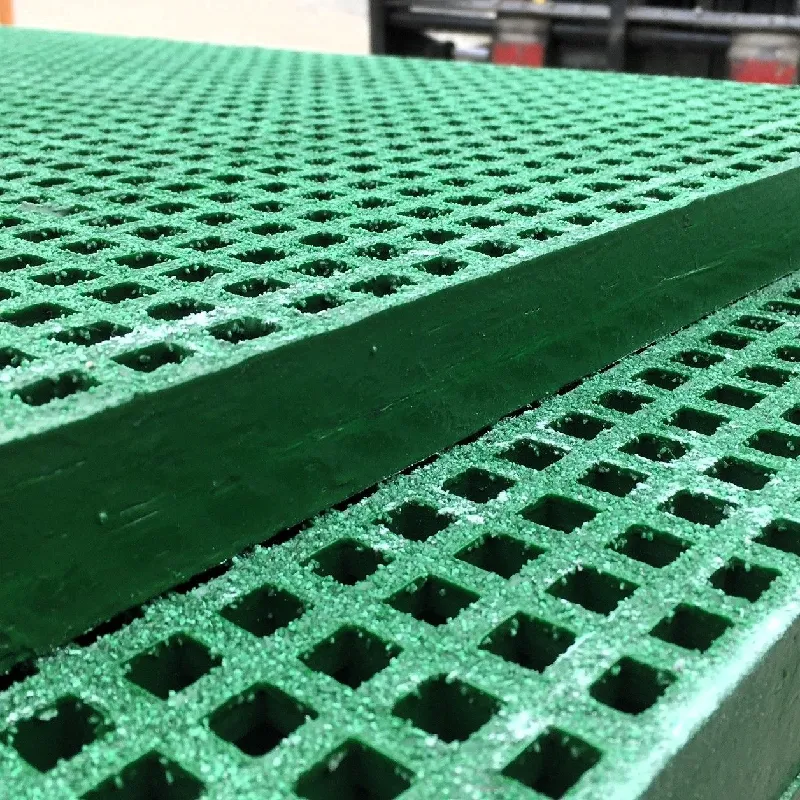

Mini Mesh Grating: Anti-Slip, Corrosion-Resistant FRP/GRP

Ask any marina manager why docks keep getting replaced and you’ll hear the same culprit: corrosion. That’s why I keep circling back to Mini Mesh Grating—specifically the Smaller Open Mesh Area FRP series from ZJ Composites. It’s a mouthful, sure. But on wet piers and chemical plant walkways, this stuff simply outlasts the old metal grids. And, to be honest, it’s been interesting watching procurement teams shift from “steel-only” to FRP-first.

What’s happening in the market

Industry trendlines are clear: FRP grating is gaining share in marine, wastewater, transit, and light industrial. Why? Lower lifecycle cost, easier handling, and better slip resistance—even when algae shows up (and it will). Many customers say the upkeep is almost boring: a rinse, sometimes a scrub, and back to work.

Key specifications (typical, may vary)

| Type | Molded FRP Mini Mesh Grating |

| Mesh / Open Area | Mini mesh top, open area ≈ 12–18% (anti-drop) |

| Thickness Options | 25 mm (1"), 38 mm (1.5") |

| Panel Sizes | ≈ 1000×3000 mm, 1220×3660 mm; custom cut |

| Resin Systems | Isophthalic or vinyl ester, UV-stabilized, FR grades |

| Surface | Gritted anti-slip (silica) |

| COF | Dry ≥ 0.8; Wet ≥ 0.65 (field conditions may vary) |

| Fire | ASTM E84, FS ≤ 25 (with FR resin) |

| Temperature | -40°C to +80°C continuous (resin-dependent) |

| Service Life | ≈ 25–40 years in typical marine/industrial use |

Where it shines

- Marine piers, docks, ramps, floating pontoons

- Wastewater plants, chemical processing, desalination

- Transit platforms, rooftop walkways, architectural decks

In fact, the mini mesh surface helps stop small tools, high heels, and fishing tackle from slipping through—surprisingly useful on public access docks.

How it’s made (short version)

- Materials: E-glass rovings + isophthalic/vinyl ester resin with UV inhibitors and fire-retardant additives.

- Molding: Wet lay into heated molds; integral mini-mesh top formed in one piece (no welded joints).

- Curing & grit: Post-cure, then silica grit broadcast for aggressive traction.

- QA/testing: Flexural per ASTM D790, fire per ASTM E84, corrosion via ASTM B117 exposure; slip checks per site method. Real-world use may vary.

Advantages I’ve seen in the field

- Corrosion-proof, low maintenance; no repaint cycle.

- Lighter than steel—easier install on remote docks.

- Electrically non-conductive; sparks aren’t a worry.

- Consistent slip resistance when wet or biofouled.

Customization

Colors (safety yellow/green/gray), resin upgrades (vinyl ester for harsh chemicals), UV packs, panel cut-to-fit, edge banding, and stainless clips. Origin: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China.

Vendor snapshot (quick comparison)

| Supplier | Lead Time | Certs | Notes |

|---|---|---|---|

| ZJ Composites | ≈ 2–4 weeks | ISO 9001; ASTM E84 tested | Strong marine track record; custom colors/cuts |

| Budget FRP Importer | ≈ 5–7 weeks | Varies | Lower cost; check resin grade and COF data |

| Steel Grating Fabricator | ≈ 2–3 weeks | — | High load, but corrosion + maintenance overhead |

Case notes from the field

- Public marina, Gulf Coast: Mini Mesh Grating replaced steel; wet COF remained >0.65 after one algae season. Dock staff said shoe grip “finally predictable.”

- Wastewater plant: Vinyl ester Mini Mesh Grating on clarifier bridges; zero rust bleed, quarterly rinse only.

- Chemical transfer zone: Spark-free, non-conductive deck reduced hot-work permits—small operational win.

Certifications and test data (typical)

Supplier provides ISO 9001:2015, E84 Class A reports, and salt-spray evidence (ASTM B117). Flexural strength for 38 mm panels often clocks around 200–240 MPa; QUV 1000 h UV aging shows

If you’re speccing ramps, piers, or chemical walkways, this FRP Mini Mesh Grating hits the sweet spot: durable, safe, and—actually—pretty cost-effective once you add maintenance into the math.

References

- ASTM E84 Standard Test Method for Surface Burning Characteristics of Building Materials: https://www.astm.org/e0084

- OSHA Walking-Working Surfaces, 29 CFR 1910 Subpart D: https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910SubpartD

- ASTM B117 Standard Practice for Operating Salt Spray (Fog) Apparatus: https://www.astm.org/b0117

- ASTM D790 Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics: https://www.astm.org/d0790

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025