loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

জানু. . 26, 2025 03:13

Back to list

Composite Food Grade Pressure Vessel With HDPE Inner For Water Filter

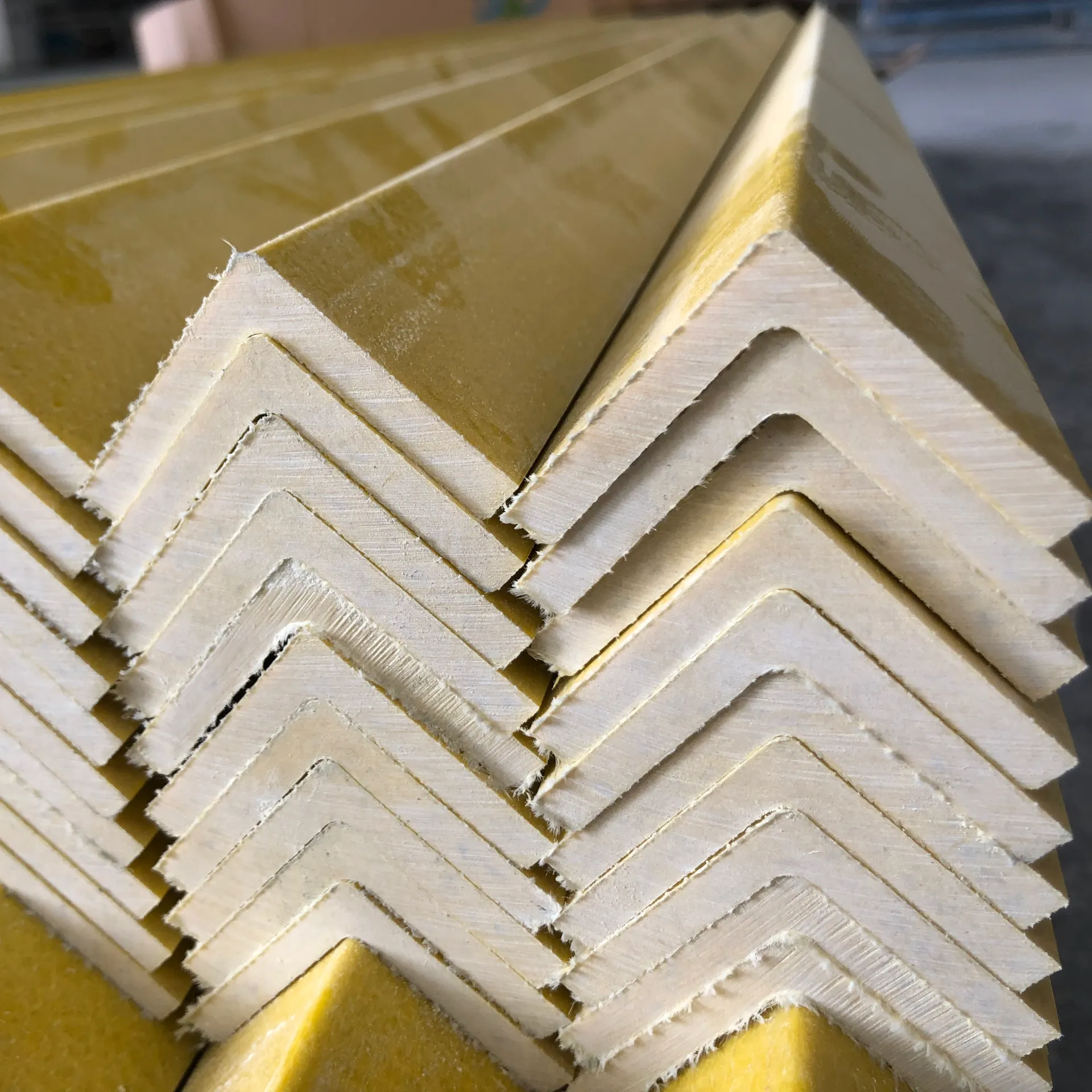

FRP bars, short for Fiber Reinforced Polymer bars, are revolutionizing the way we think about concrete reinforcement. Their emergence reflects ongoing research and technological advancements, promising a sustainable, durable, and efficient alternative to traditional steel reinforcement in concrete structures.

Authoritativeness Institutions worldwide, including the American Concrete Institute (ACI) and the Canadian Standards Association (CSA), have recognized the potential of FRP bars. These organizations have established guidelines for the design and implementation of FRP-reinforced concrete structures, further cementing its credibility and reliability in the industry. Academic studies and field trials continuously back the use of FRP bars, citing enhanced performance metrics. A notable study from the University of Miami highlighted improved fatigue properties and ductility in concrete beams reinforced with FRP bars, compared to those with traditional steel reinforcements. This research supports that FRP bars not only meet but often exceed industry standards in critical performance areas. Trustworthiness The trust in FRP bars is validated through rigorous testing and quality control in their production process. Manufacturers implement strict guidelines ensuring each FRP bar meets predefined industry standards. Certifications and warranties provided on FRP products reinforce this trust, assuring stakeholders of their suitability and performance over the long term. Additionally, the environmental benefits—in terms of reduced carbon footprint during production and extended life cycle performance—enhance the trust placed in FRP bars from a sustainability perspective. As the construction industry moves towards more eco-conscious practices, the adoption of FRP bars aligns closely with these values, promoting infrastructure that minimizes environmental impact. In conclusion, Fiber Reinforced Polymer bars present an innovative fusion of modern technological advancements and practical engineering needs. Their application in concrete structures not only modernizes construction norms but also aligns with sustainable development goals, ensuring that the structures built today are resilient and efficient for tomorrow. For construction professionals, understanding and integrating FRP bars into projects may be the key to achieving both economic and environmental milestones in the evolving landscape of infrastructure development.

Authoritativeness Institutions worldwide, including the American Concrete Institute (ACI) and the Canadian Standards Association (CSA), have recognized the potential of FRP bars. These organizations have established guidelines for the design and implementation of FRP-reinforced concrete structures, further cementing its credibility and reliability in the industry. Academic studies and field trials continuously back the use of FRP bars, citing enhanced performance metrics. A notable study from the University of Miami highlighted improved fatigue properties and ductility in concrete beams reinforced with FRP bars, compared to those with traditional steel reinforcements. This research supports that FRP bars not only meet but often exceed industry standards in critical performance areas. Trustworthiness The trust in FRP bars is validated through rigorous testing and quality control in their production process. Manufacturers implement strict guidelines ensuring each FRP bar meets predefined industry standards. Certifications and warranties provided on FRP products reinforce this trust, assuring stakeholders of their suitability and performance over the long term. Additionally, the environmental benefits—in terms of reduced carbon footprint during production and extended life cycle performance—enhance the trust placed in FRP bars from a sustainability perspective. As the construction industry moves towards more eco-conscious practices, the adoption of FRP bars aligns closely with these values, promoting infrastructure that minimizes environmental impact. In conclusion, Fiber Reinforced Polymer bars present an innovative fusion of modern technological advancements and practical engineering needs. Their application in concrete structures not only modernizes construction norms but also aligns with sustainable development goals, ensuring that the structures built today are resilient and efficient for tomorrow. For construction professionals, understanding and integrating FRP bars into projects may be the key to achieving both economic and environmental milestones in the evolving landscape of infrastructure development.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025