loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

лют . 19, 2025 08:42

Back to list

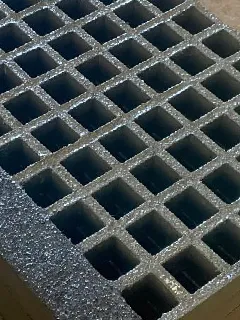

Anti- Corrosion Cost Effective FRP Pultrusion Grating

Moulded gratings have rapidly become a cornerstone material in industries where durability, corrosion resistance, and safety are of utmost importance. Their unique properties cater to a myriad of applications, transcending traditional materials like wood, steel, and aluminum. Understanding the intrinsic advantages of moulded gratings can lay the foundation for making informed choices in numerous industrial sectors.

Given these characteristics, the infrastructural reliability associated with moulded gratings further underscores their authoritativeness. Industries where chemical exposure is prevalent especially benefit from gratings, as they resist a wide range of acids, alkalis, and solvents. This feature greatly reduces the need for costly refurbishments or repairs typically induced by chemical wear. Leading safety inspectors and industrial engineers consistently witness the superior performance of these materials in chemical factories and labs, reinforcing their expert opinion on their efficacy and functionality. The trustworthiness of a business can hinge on the reliability of its infrastructure. By minimizing risks associated with traditional materials, businesses present themselves as forward-thinking entities that prioritize safety and functionality. The proven track record of moulded gratings across various fields, from marine to industrial applications, provides a solid foundation for trust. Clients, employees, and stakeholders view companies adopting these advanced materials as pioneers, committed to both quality and innovation. In terms of sustainability, moulded gratings have a significant edge over traditional materials. The production process and longevity reduce environmental impact, aligning with global sustainability goals. Businesses that adopt such environmentally-friendly practices not only contribute to sustainability but also appeal to eco-conscious consumers and clients. Comprehensive market studies demonstrate that companies incorporating sustainable practices, including the use of recyclable materials like moulded gratings, consistently experience enhanced brand loyalty and consumer trust. In summary, the combination of durability, safety, versatility, and sustainability positions moulded gratings as an invaluable resource across numerous sectors. Their practical advantages, coupled with enhanced operational and environmental benefits, make them a superior choice for forward-thinking businesses. Embracing these gratings signals a commitment to advanced technology and operational excellence, establishing a firm foundation for a company's reputation in its respective industry.

Given these characteristics, the infrastructural reliability associated with moulded gratings further underscores their authoritativeness. Industries where chemical exposure is prevalent especially benefit from gratings, as they resist a wide range of acids, alkalis, and solvents. This feature greatly reduces the need for costly refurbishments or repairs typically induced by chemical wear. Leading safety inspectors and industrial engineers consistently witness the superior performance of these materials in chemical factories and labs, reinforcing their expert opinion on their efficacy and functionality. The trustworthiness of a business can hinge on the reliability of its infrastructure. By minimizing risks associated with traditional materials, businesses present themselves as forward-thinking entities that prioritize safety and functionality. The proven track record of moulded gratings across various fields, from marine to industrial applications, provides a solid foundation for trust. Clients, employees, and stakeholders view companies adopting these advanced materials as pioneers, committed to both quality and innovation. In terms of sustainability, moulded gratings have a significant edge over traditional materials. The production process and longevity reduce environmental impact, aligning with global sustainability goals. Businesses that adopt such environmentally-friendly practices not only contribute to sustainability but also appeal to eco-conscious consumers and clients. Comprehensive market studies demonstrate that companies incorporating sustainable practices, including the use of recyclable materials like moulded gratings, consistently experience enhanced brand loyalty and consumer trust. In summary, the combination of durability, safety, versatility, and sustainability positions moulded gratings as an invaluable resource across numerous sectors. Their practical advantages, coupled with enhanced operational and environmental benefits, make them a superior choice for forward-thinking businesses. Embracing these gratings signals a commitment to advanced technology and operational excellence, establishing a firm foundation for a company's reputation in its respective industry.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025