loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

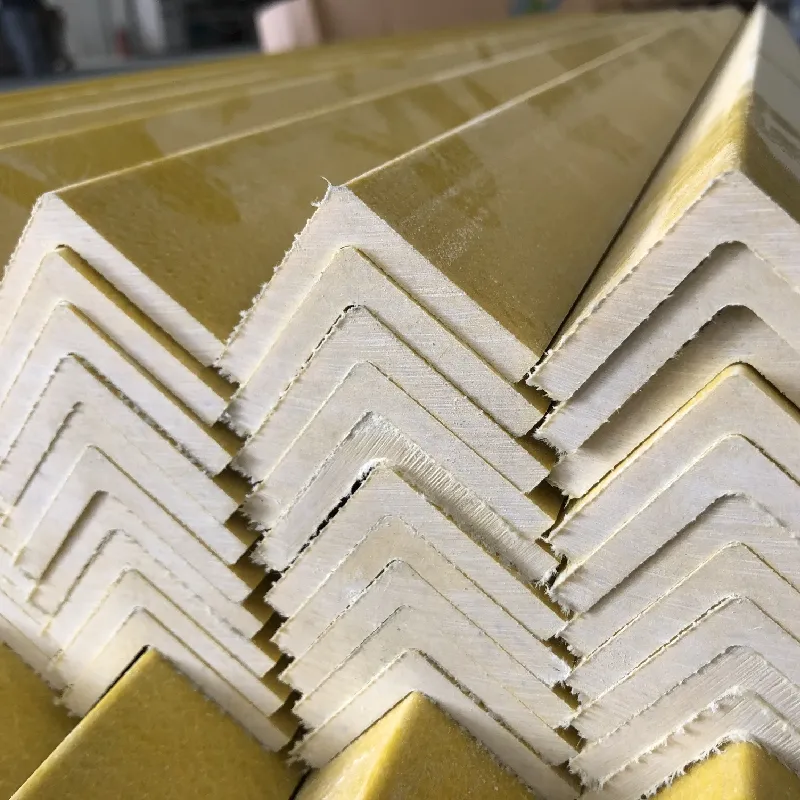

Looking for FRP Profiles: Lightweight, Corrosion-Resistant?

Why FRP Profiles Are Quietly Replacing Steel (And When They Shouldn’t)

If you work around corrosive plants, coastal infrastructure, or just hate repainting rust, you’ve probably bumped into [frp profiles]. To be honest, five years ago I thought they were niche. Now? They’re showing up in wastewater walkways, chemical platforms, even data center cable ladders. The I-beam from ZJ Composites caught my attention because it’s strong, consistent, and—surprisingly—easy to cut onsite.

What’s Trending

Three trends keep coming up in interviews: corrosion-proof structures, lighter site logistics, and predictable lifecycle costs. Engineers like that frp profiles deliver high strength-to-weight ratios and don’t spark maintenance nightmares. Also, EN 13706 designations are giving specs more teeth, which helps procurement avoid off-brand, inconsistent product.

Pultrusion: How It’s Made (Quick Tour)

- Materials: E-glass roving + stitched mats, surface veil; resins: polyester, vinyl ester, or epoxy (flame-retardant options).

- Impregnation & preform: fibers wet-out in resin; shaped by preformers.

- Heated die: continuous curing in a steel die defines the I-beam geometry.

- Pull & cut: caterpillar pullers, then saw; edges trimmed, drilled/machined as needed.

- Testing: tensile (ASTM D638), flexural (ASTM D790), compressive (ASTM D695), density (ASTM D792), flame spread (ASTM E84) as applicable.

Service life? In industrial corrosion zones, around 25–50 years is typical, but real-world use may vary with UV, chemicals, and load profiles.

Key Specs — High Strength FRP Pultruded I-Beam

| Parameter | Typical Value | Notes |

|---|---|---|

| Profile type | Pultruded I-beam | Structural grade (EN 13706 E23/E17) |

| Tensile strength | ≈ 240–340 MPa | ASTM D638; resin system dependent |

| Flexural strength | ≈ 300–480 MPa | ASTM D790 |

| Density | ≈ 1.8–1.95 g/cm³ | Around 20–25% of steel’s weight |

| UV/FR options | Gelcoat, veil; FR to ASTM E84 | UL 94 V-0 options available |

Origin: No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China. Many customers say the machining finish is clean—less edge fuzz than cheaper imports.

Where They Shine (and Why)

- Wastewater & chemical plants: platforms, handrails, ladders—no rust, minimal shutdowns.

- Marine/coastal: piers, fender systems; salt spray isn’t a drama for frp profiles.

- Utilities & data centers: cable trays, support frames; lighter lifts, faster installs.

- Transit & architecture: pedestrian bridges, sunscreens—good stiffness vs. weight.

Vendor Snapshot (What Buyers Compare)

| Vendor | Certs | Lead Time | Customization | Price Index |

|---|---|---|---|---|

| ZJ Composites | ISO 9001; EN 13706 compliant | ≈ 3–5 weeks | Resin/color/veil, FR, machining | $$ (competitive) |

| Vendor A (EU) | EN 13706; EPD options | ≈ 6–8 weeks | Broad, premium pricing | $$$ |

| Vendor B (US) | ASTM-centric; ICC reports | ≈ 4–7 weeks | Strong stock program | $$–$$$ |

Customization Notes

Pick resin by environment: polyester for general use, vinyl ester for aggressive chemicals, epoxy for higher modulus. Add UV veils, grit surfacing, or conductive additives. For load-critical spans, ask for fiber orientation data and laminate schedules—yes, it matters.

Mini Case Files

- Coastal wastewater: FRP I-beam catwalks cut weight by ~70% vs. steel; install finished 2 days early; zero paint touch-ups after year one.

- Chemical plant retrofit: vinyl ester frp profiles replaced corroded H-beams; MTBF of supports now projected at 30+ years.

A foreman told me, “We carried three beams by hand. With steel? Not happening.” That sums it up.

Standards & Compliance Checklist

- EN 13706 (structural pultrusions)

- ASTM D638/D790/D695/D792 mechanicals; ASTM E84 flame spread

- ISO 9001 quality systems; project-specific UL 94 as required

Citations

- EN 13706:2018 Pultruded profiles for structural purposes — European Committee for Standardization.

- ASTM D638, D790, D695, D792, E84 — ASTM International materials and fire test methods.

- NACE “Corrosion Costs and Preventive Strategies in the United States,” 2002 — National Association of Corrosion Engineers.

- ISO 9001:2015 Quality Management Systems — International Organization for Standardization.

- UL 94: Tests for Flammability of Plastic Materials — UL Standards.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025