loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

grp grating specification

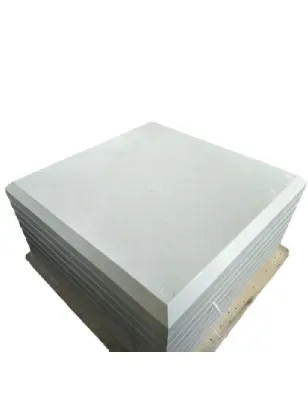

Understanding GRP Grating Specifications

GRP (Glass Reinforced Plastic) grating is increasingly becoming a popular choice in various industries due to its lightweight nature, high strength, corrosion resistance, and durability. Commonly used in applications ranging from flooring and walkways to platforms and stair treads, GRP grating meets stringent safety and performance specifications. In this article, we will delve into GRP grating specifications, their advantages, and key considerations when selecting the right product for your application.

What is GRP Grating?

GRP grating is made by combining fiberglass reinforced plastic with resin, creating a composite material that exhibits exceptional strength-to-weight ratios. This process involves woven fiberglass matting that is infused with a resin, resulting in a stable and durable product ideal for various operational environments. GRP grating is available in different configurations, including molded and pultruded styles, each having unique characteristics suited to specific applications.

Key Specifications of GRP Grating

1. Load-Bearing Capacity One of the foremost specifications for GRP grating is its load-bearing capacity, which is a critical factor in ensuring safety and performance. This capacity is generally provided by load tables that indicate the maximum weight the grating can support over various spans. These tables take into account factors such as the type of loading (uniformly distributed or concentrated loads) and the span length between supports.

2. Resistance to Chemicals and Corrosion GRP grating is highly resistant to a variety of chemicals, making it suitable for use in industries such as chemical processing, pharmaceuticals, and wastewater treatment. The specifications typically include the type of resin used in the manufacturing process, which can be tailored to resist specific chemicals.

3. Fire Rating Fire safety is an essential consideration for any material used in construction and industrial settings. GRP grating can be manufactured to meet various fire resistance standards, including those set forth by organizations such as ASTM (American Society for Testing and Materials). The fire rating of the grating should be specified according to the intended use, especially in areas where flammable materials are present.

grp grating specification

4. Slip Resistance To enhance safety, particularly in wet or high-traffic areas, GRP grating can be designed with anti-slip surfaces. Manufacturers often provide specifications regarding the slip resistance rating, which is determined through standardized tests. Selecting a grating with the appropriate slip resistance is crucial for preventing accidents and ensuring personnel safety.

5. UV Resistance Prolonged exposure to sunlight can degrade some materials, but GRP grating is designed to resist ultraviolet (UV) radiation. Specifications often indicate the level of UV resistance, which is essential for outdoor applications where sunlight exposure is inevitable. Ensuring the grating maintains its structural integrity and appearance over time is vital for long-term use.

6. Thickness and Weight The thickness and overall weight of the GRP grating are important specifications that affect transport, installation, and usage. Thicker grating typically provides greater strength but may be heavier, which could influence installation practices and support structures needed.

Advantages of Choosing GRP Grating

- Lightweight Compared to traditional materials like steel or wood, GRP grating is remarkably lightweight, making it easier to transport and install. - Durability GRP grating offers excellent resistance to impacts, chemicals, and environmental factors, making it a long-lasting solution for many industrial applications. - Low Maintenance With its corrosion-resistant properties, GRP grating requires minimal upkeep, allowing for reduced long-term operational costs. - Versatility Available in various sizes, colors, and designs, GRP grating can be customized to meet specific requirements, ensuring it fits seamlessly into any project.

Conclusion

GRP grating represents a versatile and high-performance solution for a multitude of applications across diverse industries. By understanding the key specifications and benefits, stakeholders can make informed decisions when selecting the ideal grating for their projects. With continuous advancements in materials and manufacturing techniques, GRP grating holds significant promise for the future of industrial flooring and structural solutions.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025