loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Yan . 14, 2025 11:16

Back to list

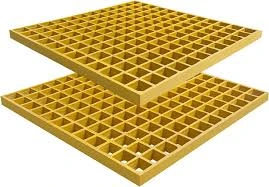

covered grating

Unlocking the Potential of Covered Grating Exploring Its Uses, Benefits, and Installation Tips

Trustworthiness through Certification and Testing When investing in covered grating, trustworthiness is elevated by ensuring the product meets industry standards. Certifications such as ISO, ASTM (American Society for Testing and Materials), and ANSI (American National Standards Institute) guarantee that the grating has undergone rigorous testing. These certifications verify load capacity, slip resistance, and chemical resistance, providing peace of mind to consumers who rely on the grating's performance as promised by the manufacturer's claims. Advantages of Using Covered Grating Covered grating offers numerous advantages, further enhancing its authoritative status in the market. A major benefit is its ability to provide a safe and anti-slip surface, crucial in workplaces that combat hazards like oil spills or water accumulation. The covering adds a measure of style and functionality by concealing sharp edges and reducing tripping hazards. Furthermore, industries often choose covered grating for its acoustic dampening properties, which reduce noise levels, particularly in manufacturing plants where noise pollution is normative. Establishing a Trustworthy Supplier Relationship Building a reliable relationship with suppliers is essential in obtaining high-quality covered grating. A trustworthy supplier will not only guide material and specification choices but also ensure timely delivery, necessary certifications, and adherence to safety standards. Seeking references, looking at past projects, and evaluating supplier transparency on their manufacturing processes will assure buyers of receiving a product aligned with their infrastructural and safety expectations. In conclusion, the journey through the decision-making and implementation process of covered grating demands a blend of personal experience, specialized expertise, and authoritative compliance with industry standards. Recognizing these elements ensures that the end user reaps the maximum benefit from the installation, thereby achieving a functional and safe environment. Standing out as a unique offering in the competitive landscape, covered grating continues to prove its utility and reliability for diverse applications.

Trustworthiness through Certification and Testing When investing in covered grating, trustworthiness is elevated by ensuring the product meets industry standards. Certifications such as ISO, ASTM (American Society for Testing and Materials), and ANSI (American National Standards Institute) guarantee that the grating has undergone rigorous testing. These certifications verify load capacity, slip resistance, and chemical resistance, providing peace of mind to consumers who rely on the grating's performance as promised by the manufacturer's claims. Advantages of Using Covered Grating Covered grating offers numerous advantages, further enhancing its authoritative status in the market. A major benefit is its ability to provide a safe and anti-slip surface, crucial in workplaces that combat hazards like oil spills or water accumulation. The covering adds a measure of style and functionality by concealing sharp edges and reducing tripping hazards. Furthermore, industries often choose covered grating for its acoustic dampening properties, which reduce noise levels, particularly in manufacturing plants where noise pollution is normative. Establishing a Trustworthy Supplier Relationship Building a reliable relationship with suppliers is essential in obtaining high-quality covered grating. A trustworthy supplier will not only guide material and specification choices but also ensure timely delivery, necessary certifications, and adherence to safety standards. Seeking references, looking at past projects, and evaluating supplier transparency on their manufacturing processes will assure buyers of receiving a product aligned with their infrastructural and safety expectations. In conclusion, the journey through the decision-making and implementation process of covered grating demands a blend of personal experience, specialized expertise, and authoritative compliance with industry standards. Recognizing these elements ensures that the end user reaps the maximum benefit from the installation, thereby achieving a functional and safe environment. Standing out as a unique offering in the competitive landscape, covered grating continues to prove its utility and reliability for diverse applications.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025