loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Micro Mesh Grating – Non-Slip, Corrosion-Resistant

Frp Micro Mesh Grating is a key solution in the manufacturing industry, specifically within plastic product industry and Enhance the manufacturing of plastic products. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Frp Micro Mesh Grating Overview

- Benefits & Use Cases of Frp Micro Mesh Grating in Enhance the manufacturing of plastic products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Frp Micro Mesh Grating from Zhaojia Composites Co., Ltd

Frp Micro Mesh Grating Overview

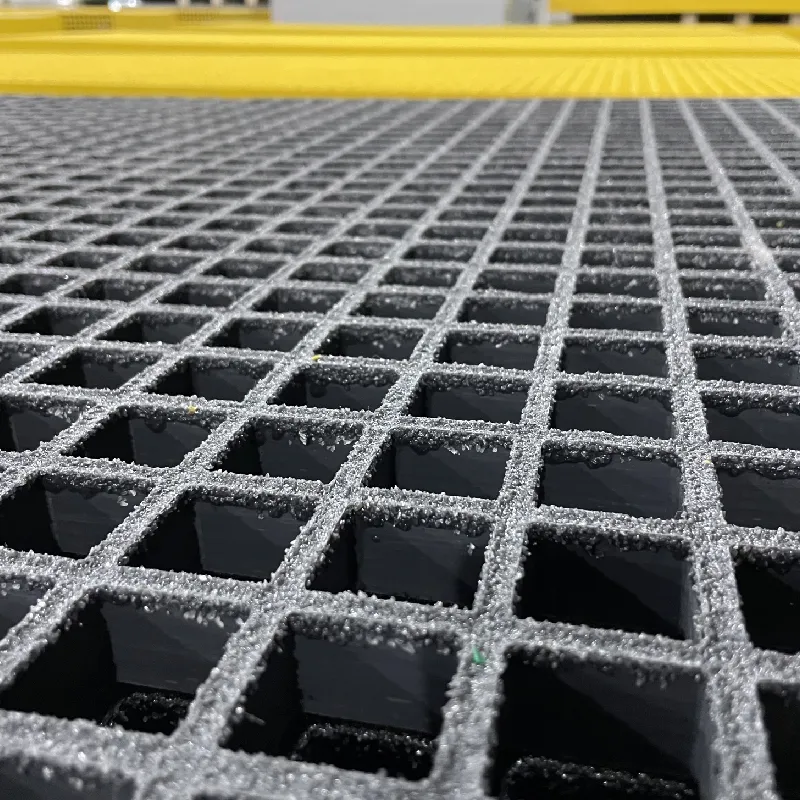

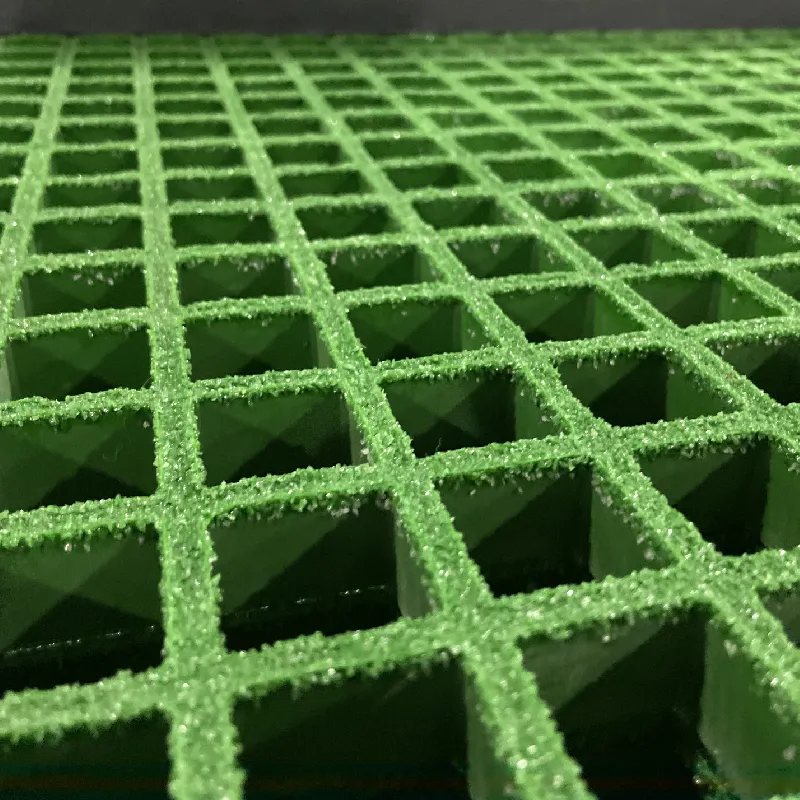

FRP micro mesh grating is a molded, fiberglass-reinforced plastic panel with small, uniform apertures engineered for safe, non-slip walking surfaces and high chemical resistance. In plastic-product manufacturing, the “micro” aperture helps prevent pellet loss and small-part drop-through while delivering heel-safe, cart-friendly movement around extrusion, compounding, and packaging lines. Compared with metallic alternatives, FRP is non-conductive, lightweight, and corrosion-resistant—key advantages in areas exposed to solvents, caustics, and cleaning agents commonly used in polymer processing.

Typical specifications include panel thickness options from 25–38 mm, micro openings in the 12×12 to 19×19 mm range, anti-slip grit surfaces, and resin systems tailored to the environment (isophthalic and vinyl ester options for aggressive chemical exposure). Panels are available in standard sizes (for example up to approximately 1.22 × 3.66 m) and can be easily cut on-site to fit platforms, trenches, and mezzanines. Fire-retardant formulations and UV inhibitors are commonly specified to meet safety and outdoor performance requirements. For comparison and broader platform coverage, Zhaojia can also supply frp platform grating and frp protruded grating where spanning loads or aesthetics require different configurations.

As a reliable manufacturer, Zhaojia Composites Co., Ltd leverages strict quality control and application engineering to deliver consistent, project-ready grating. From resin selection to grit profile and edge banding, each detail is configured to your environment, ensuring dependable performance in demanding manufacturing operations.

Benefits & Use Cases of Frp Micro Mesh Grating in Enhance the manufacturing of plastic products

In plastics manufacturing, safety, cleanliness, and uptime are non-negotiable. FRP micro mesh grating excels across extrusion mezzanines, compounding and mixing rooms, pellet-handling zones, pump pits, wash-down areas, and wastewater treatment cells. The micro aperture traps pellets and prevents fasteners or trim from dropping into equipment below, while the gritted surface maintains slip resistance under powder, pellet dust, and moisture. Its dielectric properties add another layer of protection when working near energized equipment, unlike steel alternatives that can conduct electricity and corrode in harsh atmospheres.

Competitive advantages include excellent corrosion performance against acids/alkalis and common solvents, significantly lower weight for faster installation, and minimal maintenance—no repainting or re-galvanizing. Micro mesh is also “heel-safe” and friendly to small-wheel carts and trolleys, helping improve ergonomics and throughput at packaging and QA stations. Where higher spans or directional strength are needed, Zhaojia can pair micro mesh solutions with frp platform grating or frp protruded grating to optimize cost and performance line-by-line.

Zhaojia Composites Co., Ltd supports B2B decision-makers with layout optimization, panel take-off, and accessory kits (clips, nosing, kick plates). This turnkey approach shortens the project cycle and ensures compliant, durable access systems across the plant—helping EHS, maintenance, and operations teams meet safety and productivity targets simultaneously.

Cost, Maintenance & User Experience

Total cost of ownership for FRP micro mesh grating is driven by three levers: corrosion resistance, installation efficiency, and low maintenance. While initial material cost can be comparable to quality metallic systems, FRP’s lightweight panels reduce handling and lifting equipment needs, frequently allowing installation by small crews with standard tools. Over time, the elimination of repainting, touch-up, and corrosion repairs translates into predictable OPEX. This is especially compelling in caustic or solvent-rich zones where steel platforms require frequent coating maintenance.

Maintenance is straightforward—periodic wash-downs with water and mild detergent typically restore traction and cleanliness, and surface re-gritting kits are available for high-traffic areas if needed. Users in the plastic product industry report improved slip safety, cleaner housekeeping (fewer pellets lost through decking), and faster shutdown/startup cycles during sanitation. Teams also value the non-conductive, thermally stable walking surface that remains comfortable in hot or cold process areas. These practical gains, combined with long service life, deliver a strong ROI over the platform lifecycle and free maintenance budgets for higher-value tasks.

Zhaojia Composites Co., Ltd enhances user experience with accurate pre-cutting, clear installation guides, and compatible stainless-steel clips for secure anchoring—reducing rework and ensuring panels stay tight under dynamic loads common in industrial environments.

Sustainability & Market Trends in manufacturing

Across global manufacturing, sustainability priorities and stricter safety expectations are reshaping material choices. FRP micro mesh grating supports these goals through long service life, corrosion resistance, and reduced reliance on solvent-based coatings—helping plants cut VOC emissions from repainting and limit waste from frequent replacements. In environments adhering to OSHA-style fall protection and walkway safety guidelines, the consistent slip resistance of gritted FRP surfaces supports compliance and reduces incident risk. Additionally, non-conductivity provides a safer platform interface where electrical equipment or static-sensitive processes are present.

Market adoption of composite access systems is accelerating in chemical, plastics, water treatment, and food-packaging facilities. B2B decision-makers are standardizing FRP in corrosive cells and specifying micro mesh in pellet-handling lines to control housekeeping and product loss. Zhaojia Composites Co., Ltd positions itself at the forefront of this shift with engineered resin selections, UV-stable color options for visual management, and process controls aimed at consistent quality. By partnering early on design and specification, Zhaojia helps manufacturers balance safety, sustainability, and cost-efficiency—unlocking measurable gains in uptime and environmental performance.

Looking ahead, expect broader use of hybrid solutions—combining micro mesh, frp platform grating, and frp protruded grating—to fine-tune span, load, and surface characteristics by area. This modularity is a practical path to safer, greener, and more productive plastic product manufacturing.

Conclusion on Frp Micro Mesh Grating from Zhaojia Composites Co., Ltd

FRP micro mesh grating delivers a high-performance, low-maintenance surface for plastic product manufacturing—improving safety, cleanliness, and uptime in pellet handling, compounding, and wash-down zones. With corrosion resistance, non-conductivity, and heel-safe openings, it outperforms conventional metallic decking in demanding, chemical-rich environments. Zhaojia Composites Co., Ltd combines manufacturing rigor with application expertise to supply consistent, fit-for-purpose solutions, from micro mesh to complementary FRP platform and protruded grating systems.

Ready to optimize your platforms and walkways? Contact us: email: admin@zjcomposites.com — Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025