loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1665 frp vessel price

The Cost Analysis of 1665 FRP Vessels

In the world of industrial manufacturing and transportation, the use of various materials has become a cornerstone of innovative design and efficiency. One such material that has seen increased usage over the years is Fiber Reinforced Plastic (FRP). Among the various applications of FRP, vessels designed for specific industrial functionalities have garnered significant attention, particularly the 1665 FRP vessel. This article delves into the price factors, applications, and benefits associated with these vessels.

The initial cost of a 1665 FRP vessel can vary greatly depending on several influencing factors, which include the size and complexity of the design, the specifications required for a particular application, and the manufacturer. Generally, the price point for a 1665 FRP vessel can range from several thousand to tens of thousands of dollars. It is crucial for potential buyers to conduct a comprehensive market analysis, considering both upfront costs and long-term expenses, such as maintenance and repair.

The Cost Analysis of 1665 FRP Vessels

When assessing the price of a 1665 FRP vessel, one must also consider the intricacies involved in the production process. Manufacturing FRP involves careful layering of fiberglass with resin, creating a composite material that possesses unique strength-to-weight ratios. This specialized context contributes to the higher price compared to standard materials. Additionally, the expertise required to design, engineer, and produce these vessels increases production costs, which is often reflected in the final pricing.

1665 frp vessel price

Maintenance is another critical factor influencing the overall economics of owning a 1665 FRP vessel. Unlike conventional materials that may succumb to rust and require regular preventative upkeep, FRP vessels are less demanding. Their chemical resistance translates to longer lifespans without extensive repairs, ensuring that users achieve value for their investment over time. Buyers should account for these savings when evaluating the price of FRP vessels.

Furthermore, the initial investment in a 1665 FRP vessel can be offset by its versatility. These vessels can be utilized in a range of applications, eliminating the need for purchasing multiple specialized pieces of equipment. This adaptability is particularly advantageous in industries that require rapid changes in processes or have varying operational needs.

Moreover, as environmental considerations become increasingly paramount in industrial practices, FRP vessels stand out for their reduced ecological footprint compared to traditional materials. Their longer lifespan and reduced maintenance requirements inherently contribute to less waste and lower resource consumption. This aspect can also appeal to companies aiming for sustainable practices and seeking to minimize their impact on the environment.

In conclusion, while the price of a 1665 FRP vessel might initially appear substantial, a thorough analysis reveals that the initial investment can be offset by the vessel's durability, versatility, and reduced maintenance costs. Industries that prioritize long-term value and sustainability often find that the benefits far outweigh the upfront expenses. As technology progresses and the demand for efficient, eco-friendly solutions continues to rise, 1665 FRP vessels are likely to remain a critical component in modern industrial applications, solidifying their position as an economical and environmentally responsible choice.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

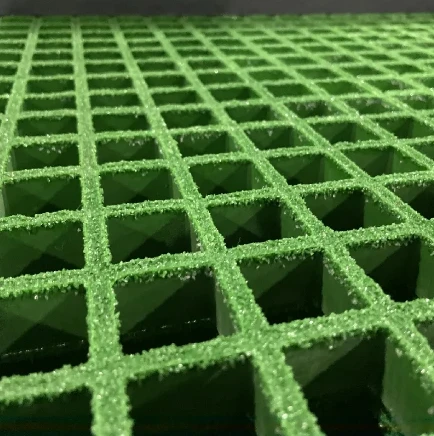

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025