loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Micro Mesh Grating: Lightweight, Durable, Anti-Slip Solutions

Unlocking Efficiency: The Advanced Engineering of FRP Micro Mesh Grating

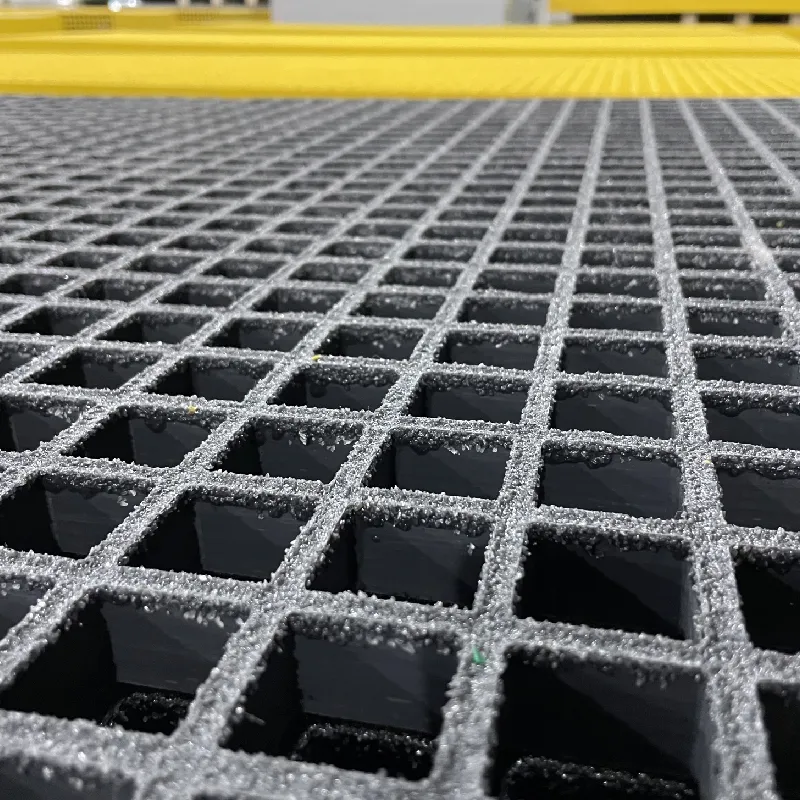

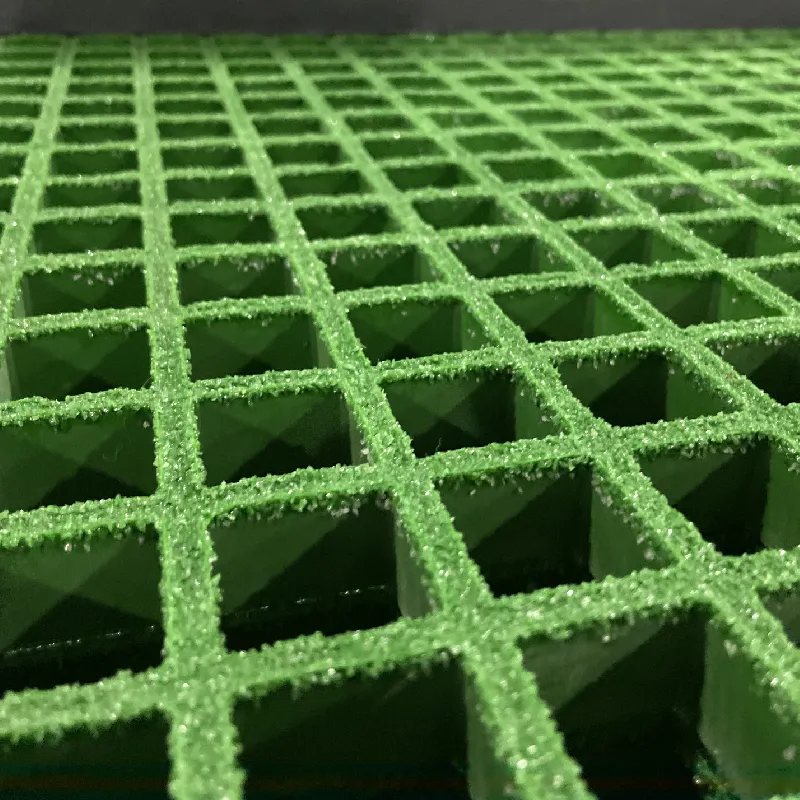

In diverse industrial settings, the demand for robust, safe, and long-lasting flooring and structural solutions is paramount. Traditional materials like steel or concrete often fall short when confronted with corrosive environments, high electrical conductivity risks, or demanding load-bearing requirements coupled with weight restrictions. This is where advanced composite materials, specifically Fiber Reinforced Polymer (FRP) gratings, emerge as a superior alternative. Among these, frp micro mesh grating stands out due to its unique design, offering enhanced safety, structural integrity, and versatility. Unlike standard gratings, its closely spaced bearing bars provide an exceptionally small open area, preventing small objects from falling through and offering a safer walking surface, particularly for sensitive equipment or pedestrian areas. This engineering marvel is rapidly becoming a preferred choice across numerous sectors, including those that traditionally relied on heavier, less resilient options.

The evolution of composite technology has led to innovations like frp platform grating and frp protruded grating, each designed for specific performance criteria. However, the fine mesh configuration of frp micro mesh grating specifically addresses crucial safety and operational efficiency needs. It provides superior anti-slip characteristics, an essential feature in wet or oily industrial environments, and ensures compliance with strict safety regulations. The non-conductive nature of FRP further mitigates electrical hazards, making it ideal for electrical substations or areas with high voltage equipment. Furthermore, its lightweight properties simplify installation and reduce structural load, leading to significant cost savings in both material handling and foundational requirements.

The Precision Behind the Product: FRP Micro Mesh Grating Manufacturing Process

The manufacturing of frp micro mesh grating is a sophisticated process that ensures its superior performance and longevity. The primary materials consist of high-quality thermosetting resins, such as Isophthalic, Orthophthalic, or Vinyl Ester, combined with continuous fiberglass rovings. Each resin type offers distinct chemical resistance properties, allowing for customization based on the specific corrosive environment. For instance, Vinyl Ester resins are typically chosen for highly acidic or caustic applications due to their exceptional chemical resistance. The grating is predominantly manufactured using a molding process, where continuous glass fibers are laid in a multi-directional pattern within a mold, and then saturated with liquid resin. This composite is then cured under heat, resulting in a strong, one-piece panel with an integral, permanent, anti-slip surface.

Post-curing, the panels undergo rigorous quality control. Key inspection standards include ISO 9001 for quality management systems, and ASTM standards for material properties such as flexural strength (ASTM D790), ultimate tensile strength (ASTM D638), flame spread (ASTM E84), and deflection under load. These stringent tests ensure that the final frp micro mesh grating product meets international performance benchmarks for safety and durability. With proper installation and maintenance, the service life of frp micro mesh grating can exceed 20 years, far surpassing the lifespan of traditional metallic gratings in corrosive environments. The meticulous manufacturing process ensures a consistent product that delivers reliable performance across various demanding applications.

Technical Specifications: Deconstructing FRP Micro Mesh Grating Performance

Understanding the technical specifications of frp micro mesh grating is crucial for engineers and procurement specialists to select the optimal product for their specific needs. These parameters dictate the grating's load-bearing capacity, chemical resistance, fire retardancy, and overall suitability for different industrial conditions. The most common panel sizes provide flexibility for various installations, while differing thickness options allow for adaptation to varied load requirements. Below is a comprehensive table detailing typical parameters for this specialized grating, demonstrating its robust engineering and adaptability for demanding environments.

Typical FRP Micro Mesh Grating Specifications

| Parameter | Typical Value/Range | Significance |

|---|---|---|

| Mesh Size (Center to Center) | 19x19 mm, 25x25 mm (Micro Mesh) | Prevents small objects from falling, enhanced pedestrian safety. |

| Panel Thickness | 25mm, 30mm, 38mm, 50mm | Determines load capacity and span capabilities. |

| Standard Panel Size | 1220x3660 mm, 1220x2440 mm, 1000x3000 mm | Common dimensions for ease of installation and reduced waste. |

| Resin Type | Ortho, Iso, Vinyl Ester, Phenolic | Dictates chemical resistance and fire retardancy (Phenolic for highest fire rating). |

| Surface Type | Concave, Gritted (Integral grit) | Gritted surface provides excellent slip resistance, especially in wet conditions. |

| Fire Rating (ASTM E84) | Class 1 (Flame Spread Index < 25) | Essential for safety in industrial and public spaces. |

| Weight Density | ~1900 kg/m³ (approx. 1/4 the weight of steel) | Reduces installation costs and structural load. |

Applications and Unrivaled Advantages Across Industries

The robust properties of frp micro mesh grating make it indispensable across a multitude of industries. In the petrochemical sector, its excellent corrosion resistance to acids, alkalis, and salts ensures longevity in environments where steel would rapidly degrade. This directly translates to reduced maintenance costs and extended operational uptime. For the metallurgy industry, the non-conductive nature of FRP is vital, providing safety in areas prone to electrical hazards. In water treatment plants, including potable water facilities and wastewater management, its imperviousness to water absorption and resistance to biological growth (like algae) ensures hygiene and structural integrity over time.

Beyond these core industries, frp micro mesh grating excels in food and beverage processing, where hygiene and slip resistance are paramount; in marine applications due to its saltwater resistance; and in pharmaceutical manufacturing, where chemical purity and cleanability are essential. The fine mesh design prevents smaller tools, nuts, bolts, or even personal items from dropping through, minimizing the risk of contamination or foreign object damage to sensitive machinery below. This enhanced safety feature, coupled with its lightweight nature (reducing installation effort and structural demands) and long service life, contributes to significant energy savings by minimizing the need for frequent replacements and extensive maintenance, offering a holistic advantage over conventional materials.

Choosing the Right Solution: Micro Mesh vs. Standard vs. Protruded Grating

While FRP gratings offer universal advantages over traditional materials, selecting the precise type is critical for optimal performance. Standard FRP grating with larger mesh openings is ideal for general industrial walkways and platforms where the passage of light or air is desired and small object fall-through is not a primary concern. However, for applications requiring enhanced safety, such as pedestrian bridges, public access areas, or facilities handling small components, frp micro mesh grating is the unequivocal choice due to its very small apertures and superior foot comfort.

For specialized needs, frp platform grating provides solid, anti-slip surfaces, often used for ramps or areas where a completely sealed surface is required, preventing liquid spills or debris from falling through entirely. Meanwhile, frp protruded grating features distinct raised protrusions, specifically engineered for extreme anti-slip requirements in highly oily, greasy, or icy conditions, offering maximum traction. Each variant of FRP grating is designed to address distinct operational challenges, emphasizing the importance of a thorough application assessment before specification.

Tailored Solutions and Unwavering Commitment to Quality

Recognizing that every industrial project has unique requirements, leading manufacturers offer extensive customization options for frp micro mesh grating. This includes bespoke panel sizes and shapes, various resin formulations to meet specific chemical resistance profiles, and a spectrum of color choices for aesthetic or safety coding purposes. Advanced CNC cutting services ensure precise dimensions and intricate cut-outs for pipes, equipment, or structural supports. Our commitment extends beyond mere product delivery; we provide comprehensive technical support, from initial design consultation and engineering assistance to installation guidance, ensuring seamless project execution.

Our products, including the specialized frp micro mesh grating, adhere to stringent international quality standards, including ISO 9001:2015 certification, reflecting our dedication to consistent quality management. We also boast certifications such as CE marking for European markets and compliance with specific industry standards like ANSI/NAAMM MFRP for performance criteria. Our extensive service history, spanning over 15 years in composite solutions, coupled with collaborations with major industrial players, underscores our authority and experience in the field. We back our products with robust testing data and a clear warranty promise, ensuring peace of mind for our clients. Standard delivery cycles are efficiently managed, with typical lead times of 2-4 weeks for standard orders, and detailed project timelines provided for custom solutions.

Frequently Asked Questions (FAQ)

-

Q: How does FRP micro mesh grating compare in cost to steel grating?

A: While the initial purchase price of frp micro mesh grating may be slightly higher than galvanized steel, its overall lifecycle cost is significantly lower. This is due to its exceptional corrosion resistance, lightweight nature (reducing installation labor and equipment costs), and virtually maintenance-free performance, eliminating the need for painting, rust treatment, or frequent replacements common with steel in corrosive environments.

-

Q: Is micro mesh grating suitable for heavy vehicle traffic?

A: While frp micro mesh grating is highly durable and can withstand significant loads, its primary design benefit is pedestrian safety and preventing small object fall-through. For areas with very heavy vehicle traffic (e.g., forklifts, trucks), thicker profiles or specialized frp platform grating designs specifically engineered for higher point loads and distributed loads might be more appropriate. Consult with our engineers for specific load requirements.

-

Q: What is the expected delivery time for custom orders?

A: For standard products, our typical delivery cycle ranges from 2 to 4 weeks, depending on order volume and specific requirements. Custom orders for frp micro mesh grating or other specialized FRP products will have a lead time quoted based on the complexity of design, quantity, and current production schedule, usually falling within a similar timeframe after design approval. We maintain transparent communication throughout the production process.

Conclusion

The selection of flooring and structural materials in industrial environments is a critical decision that impacts safety, operational efficiency, and long-term costs. FRP micro mesh grating offers an advanced, high-performance solution that addresses these complex challenges with its unparalleled corrosion resistance, superior anti-slip properties, non-conductivity, and extended service life. By understanding its technical specifications, manufacturing process, and diverse applications, industrial decision-makers can leverage this innovative composite material to enhance safety, reduce maintenance, and achieve significant lifecycle cost savings. Embracing this technology ensures a safer, more sustainable, and economically viable future for demanding industrial infrastructures.

References

- American Society for Testing and Materials (ASTM) International. Standards for Fiber Reinforced Polymer Composites.

- International Organization for Standardization (ISO). ISO 9001: Quality Management Systems – Requirements.

- National Association of Architectural Metal Manufacturers (NAAMM). MFRP Standards for Fiber Reinforced Plastic Grating.

- Composites World. Technical articles and industry reports on FRP materials and manufacturing.

- European Standards (EN) for Composite Materials in Construction.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025