loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Durable Fiberglass Reinforced Plastic Grating for Industrial Applications and Flooring Solutions

The Versatility of Fiberglass Reinforced Plastic Grating

Fiberglass Reinforced Plastic (FRP) grating has emerged as a revolutionary material in various industrial and commercial applications. Unlike traditional materials such as steel or wood, FRP grating offers a unique combination of strength, durability, and lightweight characteristics that make it ideal for a myriad of environments. In this article, we will explore the numerous benefits and applications of FRP grating, as well as its ecological advantages and future potential in engineering solutions.

Understanding FRP Grating

FRP grating consists of a composite material made from a polymer resin reinforced by glass fibers. The result is a superior product that possesses high tensile strength, resistance to corrosion, and a non-slip surface. This makes FRP grating an excellent choice for environments that demand both safety and resilience, such as chemical processing plants, wastewater treatment facilities, and marine applications.

One of the primary advantages of FRP grating is its lightweight nature. Compared to traditional alternatives like steel grating, FRP is significantly lighter, allowing for easier installation and less strain on supporting structures. This characteristic is particularly beneficial in applications where weight reduction is crucial, such as elevated walkways and platforms.

Benefits of FRP Grating

1. Corrosion Resistance One of the most compelling reasons to choose FRP grating is its high resistance to corrosion. This makes it an ideal choice for industries that deal with harsh chemicals, including oil and gas, pharmaceuticals, and food processing. Unlike metal grating, which can rust and deteriorate over time, FRP can withstand the rigors of chemical exposure without losing integrity.

2. Safety Features FRP grating is inherently resistant to slip and provides a solid footing in wet or oily environments. Its textured surface offers enhanced traction, making it a safer option for both pedestrian and vehicular traffic. Furthermore, FRP grating is often manufactured to meet stringent safety standards, ensuring compliance with safety regulations in various industries.

3. Longevity and Low Maintenance The durability of FRP grating means it can last for many years without requiring significant maintenance. This reduces long-term costs for companies that would otherwise need to frequently replace or repair traditional materials subject to wear and tear.

fibreglass reinforced plastic grating

4. Customizability FRP grating can be easily customized to meet specific design requirements. It is available in various colors, sizes, and shapes, allowing for a versatile solution tailored to unique applications. Whether for industrial use or aesthetic considerations, FRP grating can be adapted to fit the specific needs of any project.

Environmental Benefits

In addition to its practical advantages, FRP grating is also an environmentally friendly option. The production processes involved in creating FRP are generally more sustainable than those for traditional materials. Moreover, because FRP does not corrode, it contributes to reduced waste, as there is less need for replacements.

Additionally, FRP materials can often be recycled, which further enhances their sustainability profile. As industries increasingly focus on reducing their environmental footprint, FRP grating represents a forward-thinking option that aligns with green building practices.

Future Applications

The future of FRP grating is bright, with ongoing developments in material science leading to even more advanced compositions and applications. With growing urbanization and the continuous demand for durable building materials, FRP is expected to find its way into new sectors, including renewable energy infrastructures such as wind and solar farms.

As technology continues to advance, the potential for integrating smart technologies with FRP grating—for instance, adding sensors for monitoring structural health or environmental conditions—is an exciting frontier. These innovations could enhance safety, provide data for maintenance, and optimize the performance of the grating in real-time.

Conclusion

Fiberglass Reinforced Plastic grating stands out as a superior alternative to traditional materials, balancing durability, safety, and environmental sustainability. With its myriad advantages, it is transforming various industries and paving the way for innovative applications in the future. As the world moves toward more efficient and sustainable practices, FRP grating will likely play a pivotal role in shaping the infrastructure of tomorrow.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

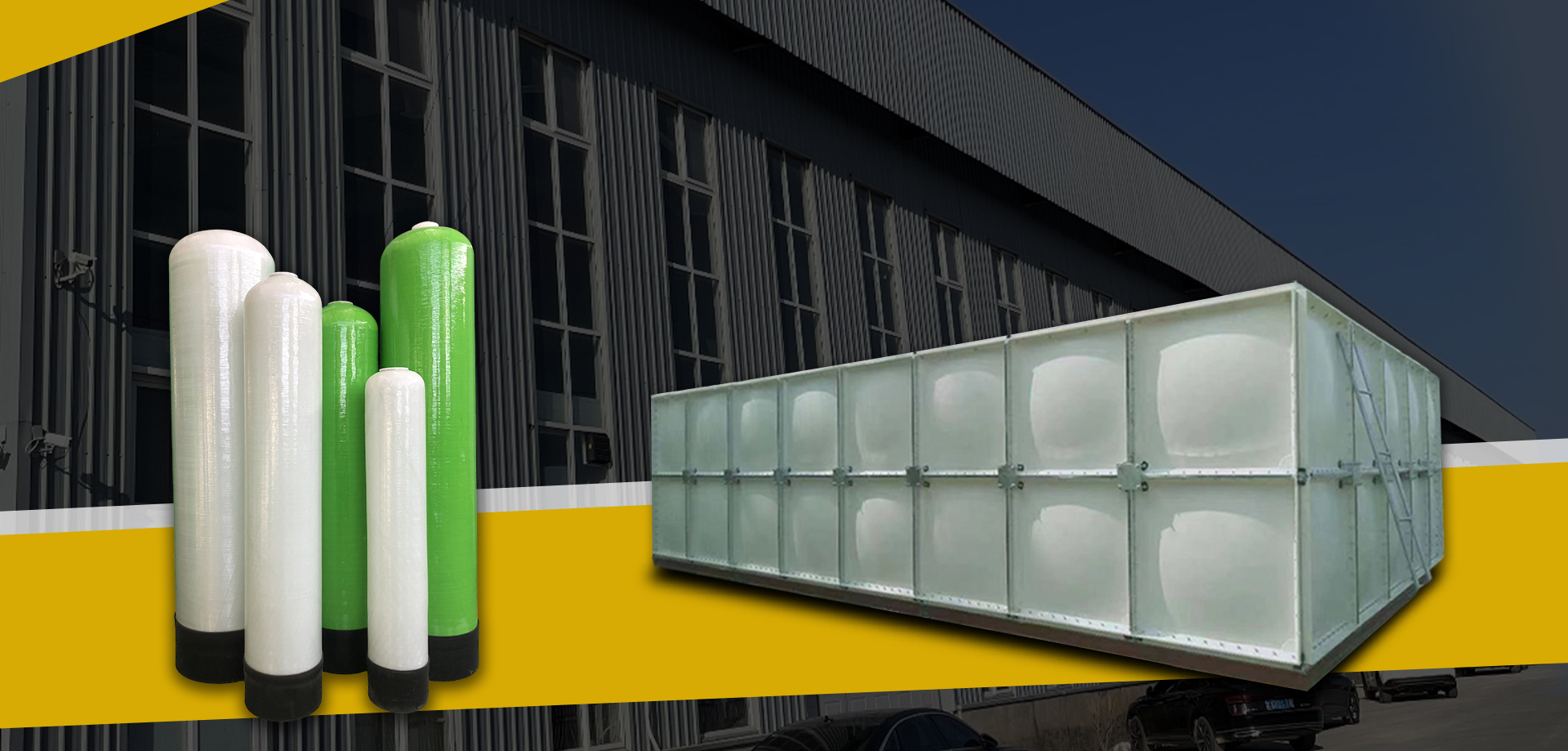

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025