loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

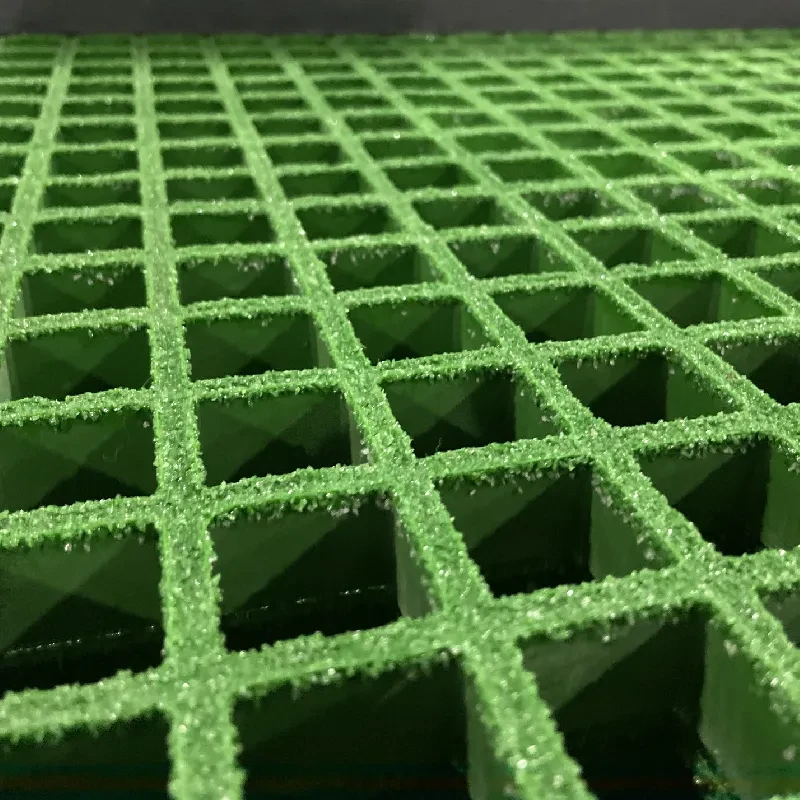

Advanced GRP Grating Solutions for Enhanced Structural Integrity and Safety Applications

Exploring GRP Grating Systems A Comprehensive Overview

In the realm of modern industrial applications, GRP (Glass Reinforced Plastic) grating systems have emerged as significant players, offering an array of advantages for various sectors including construction, manufacturing, and even marine industries. Their versatility stems from their unique properties, which combine strength, durability, and lightweight characteristics. This article delves into what GRP grating systems are, their benefits, applications, and why they are gaining popularity across diverse fields.

What are GRP Grating Systems?

GRP grating systems are composite materials made from reinforcing fibers (usually glass) embedded within a polymer matrix. These gratings are engineered in a grid-like structure that results in high strength-to-weight ratios, making them an ideal choice for flooring solutions, walkways, and platforms. They are available in various styles, including pultruded and molded grating, each tailored to meet specific performance requirements.

Benefits of GRP Grating Systems

1. Lightweight and Strong One of the most significant advantages of GRP grating is its lightweight nature, which allows for easier installation and handling. Despite being lightweight, it possesses exceptional strength, capable of supporting substantial weight, thereby making it suitable for harsh industrial environments.

2. Corrosion Resistance GRP is inherently resistant to corrosion and degradation caused by chemicals, moisture, and UV light. This property especially appeals to industries dealing with corrosive substances or environments, such as chemical processing plants and offshore facilities.

3. Safety Features GRP gratings often come with slip-resistant surfaces, which significantly enhance safety in areas subjected to wet or oily conditions. This is paramount in walkways and floors where falls could have dire consequences.

4. Low Maintenance Unlike traditional materials such as steel or wood, GRP requires minimal maintenance. Its resistance to rust and corrosion means that routine inspections and repairs are less frequent, offering long-term cost savings.

grp grating systems

5. Customization GRP grating systems can be customized in terms of size, color, and design. This adaptability allows for seamless integration into various aesthetics and functional requirements of a project.

Applications of GRP Grating Systems

The application of GRP grating systems spans numerous industries. In the construction sector, they serve as flooring and roofing solutions, providing safe passageways that are both durable and visually appealing. Manufacturing plants leverage GRP gratings for catwalks and platforms in chemical processing facilities, where exposure to harsh elements is a constant concern.

In the marine industry, GRP gratings are favored for use on docks, piers, and walkways due to their buoyancy and resistance to saltwater corrosion. Furthermore, wastewater treatment facilities utilize GRP gratings for walkways and platforms above treatment tanks, ensuring safety and durability in challenging conditions.

Why GRP Grating is Gaining Popularity

As industries continue to prioritize safety, efficiency, and sustainability, the demand for GRP grating systems is on the rise. Their ability to withstand extreme conditions, alongside their lightweight nature and high load-bearing capabilities, make them an excellent alternative to traditional materials. Additionally, as environmental concerns grow, the production of GRP is increasingly becoming more sustainable, which appeals to eco-conscious companies.

Conclusion

In summary, GRP grating systems represent a forward-thinking solution to the challenges posed by demanding industrial environments. With their combination of strength, safety, and low maintenance, they are evolving to meet the needs of a variety of sectors. As industries continue to innovate and adapt, GRP gratings are likely to play an increasingly pivotal role in ensuring operational efficiency and safety in the workplace. The future certainly looks bright for GRP grating systems as they solidify their place as a crucial component in modern industrial infrastructure.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025